This blog is part of the Collaborative Working Champions series of ten blogs on Modern Collaborative Working

Beauty is in the eye of the beholder, as the saying goes, meaning each of us has our own personal scale of what we find attractive and what we don’t. Sometimes our scale agrees with that of others and sometimes it’s completely different. So is it the same with Value? There are certainly different perspectives of what is of value or valuable, but is there a way of quantifying value in relation to construction activity that makes it comparable for us all?

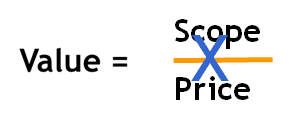

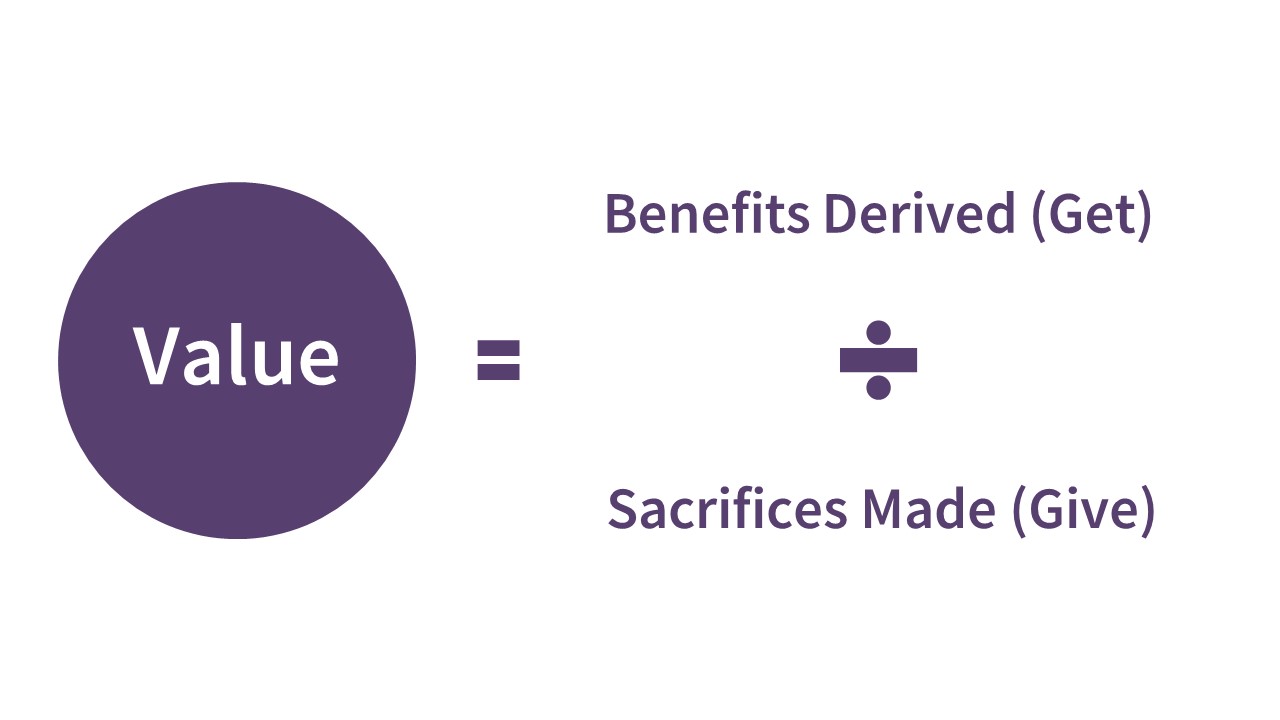

If you have ever heard Richard Saxon (current chair of JCT and former chair of BE one of the founding members of CE) speaking on the subject, you might think there is. Richard eloquently suggests that value is determined by considering all the benefits you are able to receive or “what you will get” and dividing this by all the sacrifices you have to make in order to receive these benefits i.e. “what you have to give” which can then be presented in the form of the following equation;

Having got to this point, some can instinctively see how our industry has unknowingly leapt to a slightly different version of this equation in an attempt to provide a quantitative evaluation of tenders under the selection process. By replacing the benefits (what you get) with the scope of the requirements and the sacrifices made (what you give) with the price, they have attempted to provide a simple evaluation which says the cheapest price for the same scope will deliver the best value. But there is a problem with this; benefit is an outcome whereas scope is an input and price is similarly an offer not a result. This means the relationship between the scope being tendered for and the price that is being offered is uncertain, meaning the equation is not the same and value can’t be derived in the same way.

Relationship between Scope and Price

Let’s try and look at a simple example to quantify why the ‘tender value’ equation doesn’t provide comparable results. Suppose you want to buy a dessert spoon and you are able to completely specify the requirements (scope) of this spoon i.e. its size, weight, the material of manufacture, the shape and thickness of its handle and bowl etc. and suppose these spoons are readily made by a number of different people, then why would you not take the cheapest price you can find for as many of the spoons as you are looking for; after all, your supplier may have a shelf full of them and is only too pleased to make a small profit to shift some slow moving stock. This is our old friend commodity purchasing and it is entirely appropriate to use this method if you are truly able to find and buy fully definable commodities.

But how often are we able to provide this level of definition for a construction project? We have previously explored the folly of the design side attempting to conclude a solution without input from the delivery side (blog #2) and the problems in communicating requirements via specifications and drawings (blog #3) but there is actually a different point to be made here.

Most of us know the devil is in the detail and it is only after the misunderstandings, errors, omissions, variations, claims and negotiations are complete that we will actually know what the scope was and the price that had to be paid for it and only at completion will the value obtained be quantifiable (assuming you don’t want to wait for cost in use to be quantified too); not much good when the intention was to use it as a tender evaluation tool! However, this does provide a hint as to how to proceed.

Redefining Value

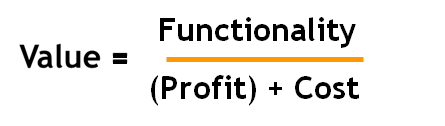

Since the important point is outcome and not offer, we need to change the equation to reflect that. We have talked before about understanding client’s needs (blog #1) and lots of people have moved to providing outcome or performance-based specifications. And whilst it would be extremely difficult to fully define all the potential benefits required, most people are fairly comfortable about writing in terms of required functionality, so let’s use that to replace Scope.

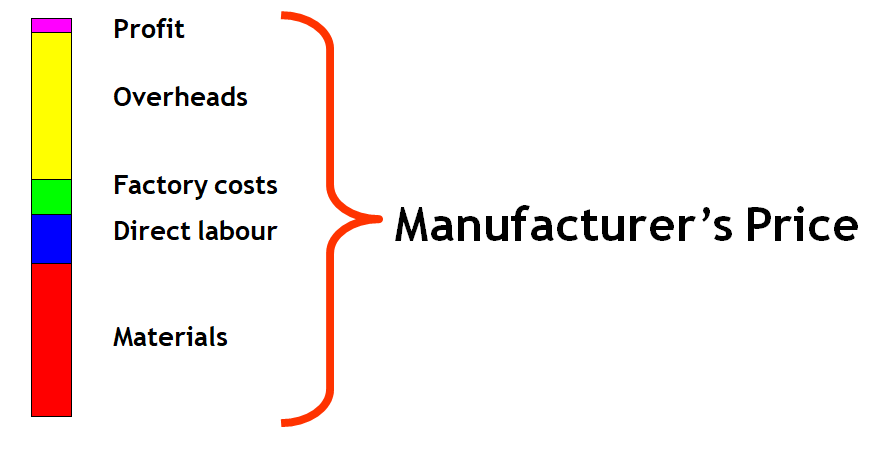

Now what about price? Many people use price and cost quite interchangeably when they speak but there is a clear distinction between the two. To illustrate this, take look at the following demonstration of a manufacturer’s business costs for which we are indebted to fellow Champion Ron Edmondson of Waterloo;

So when a manufacturer provides a price for a particular product or solution that price is made up of profit and a range of costs that include overheads. And whilst the cost base may differ, the principles are the same for any organisation with these costs essentially being hidden in the price. So we can reasonably replace the Price element with profit and cost and the equation becomes;

But we aren’t finished yet. Let’s think about the impact of working with the price now we know what it is made up of. As the client who is paying for the functionality, you ideally want the price as low as possible, then you want the maximum of your payment to go into the cost of the project rather than someone else’s profit. If you are the person delivering, you want the price to be as high as possible and as much of the payment to go into your profit as possible instead of the cost of the project. To put it another way, just by working with price you are in conflict (and this conflict is repeated up and down the supply chain). In addition, profit tends to be a relatively small proportion of the price and as it is essential for survival, any attempt to reduce it will simply be met with tactics to claw it back, if not immediately then as the project progresses. This explains why enlightened customers are seeking to ringfence profits so that everyone can focus on the right target which is the cost of the content of the project.

How to work with cost

Saying price is profit plus cost is a bit of an over-simplification and it misses the opportunities to add increasingly greater value. To start with, prices will always include risk allowances and the more customers try and push risk down the supply chain the greater this element is likely to become. However, by working with cost, which means an open book environment, all parties are able to see the risks that have been considered and the allowances that have been made for them. Risk can then be allocated to those who are best suited to manage and mitigate them and everyone’s interest will be served by minimising the impact and cost of these risk elements.

If we return to the manufacturer’s cost base, we can explore the opportunities for cost reduction that exist within every organisational set up. Starting with overhead, which incidentally many separate into corporate and project overhead and include the corporate element in the ringfenced allowance, this is influenced by the behaviours of customers in ways most never consider. For example, marketing, tendering and sales costs can all be reduced by those customers who partner with their suppliers, whilst working on repeat projects reduces the training burden and learning times; this is the reason frameworks are extensively promoted in our industry – so long as they are used in a partnering manner and not just as an OJEU avoidance tool which then requires a limited competition, thus discarding all the value we just identified.

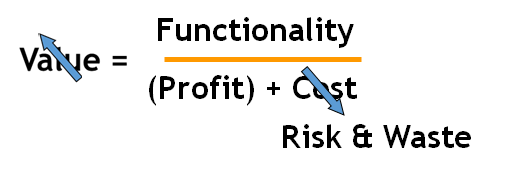

Then there is the core cost of what the organisation does where methods, procedures and inventory are often dictated by specifiers rather than developed in partnership with the suppliers leading to lost opportunities through the inefficient use of staff and physical resources, duplication, over inventory and rework. But here we are touching on the waste that pervades the industry and is perpetuated by the fragmented practices that are adopted and is the subject of our next and ninth blog in this series. However, it would be inappropriate given the direction of this blog if we did not point out that whilst superior value can be achieved by reducing the direct cost of what is necessary to provide the required functionality, this can and should be significantly increased by elimination of the risks and wastes that are inherent in those activities. Which delivers us to the final look at the value equation;

Which shows that for any given functionality, if we ringfence the profit (and corporate overhead) and find ways of reducing the cost including eliminating risk and waste, then value can be maximised without having to compromise profitability and performance of any of the team including the supply chain.

The multiplier that collaboration creates

It’s fair to say that after years of trying to deliver “more for less”, many organisations in the industry are relatively lean, at least when compared to their bloated historical selves. Whilst there are those who will always focus on corporate overhead reduction as the primary route to improve profitability, others are acutely aware of how targeted investment in one area can lead to significant improvement elsewhere; such as the way digital is transforming productivity. However, by moving away from corporate overhead, the reality for most if not all, is there are likely to be far more significant savings hidden away in the project overhead. To get some idea just how much, take a look at the research underpinning Brydon Wood’s 2019 Report ‘Delivery Platform for Government Assets’ which found that nearly half of the spend failed to add any residual value to the assets provided. So how do you unlock this value?

Working in isolation to reduce project overhead is counterintuitive. Delivering a project or programme of work is a team sport, and only through collaboration, honesty and integrity can a team become sufficiently efficient, innovative and productive. Some improvement may be achieved by avoiding duplication within the team and removing onerous man-marking within the tiers of traditional supply chains, but superior value is only going to be attained by moving to more collaborative delivery methods such as those described by the IPI (Integrated Project Insurance) Model, Project 13, DfMA (Design for Manufacture and Assembly) or Gemini Principles for digital twins. Experience shows it is those teams that work together to reduce project overhead that are generally able to deliver more value through managing out risk, eliminating waste and thus lowering cost [and price] without impacting on the intended functionality including lifecycle.

Behavioural Changes to Adopt

- Seek to understand how scope and price are interrelated.

- If you are using a commodity purchasing method be sure what you are buying is genuinely a commodity.

- Be clear about the difference between price and cost.

- Understand the impact your behaviours have on your suppliers cost base; and recognise that you pay for this.

- Some savings are only available through working together.

- Some savings are only available through working together repeatedly.

- Be clear about the contradictory objectives when working with price.

- Recognise what a poor target profit is in the delivery of savings.

- If you want more value, work out how to eliminate embedded risk and waste.

- Allocate risk by agreement and to the party best placed to manage/mitigate it.

- Understand the part design and specification play in fixing the cost (or price).

- Look to the overhead costs of a project to find value adding opportunities.

With thanks to Mike Reader (Mace Group), Paul Wilkinson (PW.com.uk ltd) and Odilon Serrano (Mott Macdonald) for their input and improvements.

Kevin Thomas – Chair and Coach of the Collaborative Working Champions of Constructing Excellence and Founding Director of Integrated Project Initiatives Ltd, the creators and delivery organisation for the Integrated Project Insurance (IPI) Delivery Model.

This blog is part of the Collaborative Working Champions series of ten blogs on Modern Collaborative Working

Comments are closed.