New delivery model:

Integrated Project Insurance

Trial project:

Derby Silk Mill – Museum of Making: Case Study 3

Key Specific Objectives

- Completion in the spring of 2020 at a cost which is at or below the agreed target cost

- An exceptional and inspiring visitor experience in a high-quality environment

- Exhibition display and interpretation that creates 100% access to collections

- Exhibition displays that can evolve and be remade on-site to create new visitor experiences and stay relevant

- Flood mitigation successfully implemented

- High quality of design and materials in keeping with conservation requirements

Download pdf: Derby MoM Case Study 3

| Stage at which first report will be published: | Kick off meeting | Brief / Team Engagement | Decision to Build | Build and Occupy |

| Cost saving basis: | Investment Target | Challenging cost target | Agreed Target Cost | Outturn cost |

Daniel Defoe’s ‘A Tour thro’ the Whole Island of Great Britain’ (1724-27) records:

“This engine contains 26,586 Wheels, and 96,746 Movements, which work 73,726 yards of Silk-thread, every time the Waterwheel goes round, which it does three times in one Minute.”

Derby Museums:

How might we use the making of the Museum of Making, to engage people’s heads, hearts and hands – empowering them to be the creators, innovators and makers of the future?

The Museum of Making, extended & restored to life

Key facts

| Project title | Derby Silk Mill – Museum of Making |

| Client | Derby Museums |

| Investment Target | £15.830m |

| Initial Target Cost | £13.325m |

| Form of project | Heritage extension and refurbishment |

| Independent facilitation and risk assurance | IPInitiatives

Technical: BLP Financial: Artelia |

| Alliance Members | Derby Museums

Bauman Lyons, architects Preston Barber, engineering GCA (UK) [replaced Adept], structural Speller Metcalfe, constructor Derry, building services Creative Core Ltd, exhibitions |

| IPI Brokers | Griffiths & Armour |

| Other Key Suppliers | Garvey: demolition and asbestos removal

Roger Bullivant: piling Adstone Construction: steel frame Façade & Glazing Solutions: curtain walling and glazing Swift Roofing Services: new roofing NRA Roofing: existing roof works Concrete Renovations: pillar restoration Independent Scaffold Services: scaffolding MSW Steel Decking UK: metal deck and concrete J&P Carpentry: carpentry MG Olympic: architectural metalwork

|

Executive summary

Derby Museums commissioned exhibition specialist Leach and architects Bauman Lyons with a design team to develop their vision for the Silk Mill as a “museum of making” for the 21st Century. Heritage Lottery and Arts Council funding was eventually secured, supplemented by funds from Derby City and local communities. Inevitably the brief for the extension and refurbishment project had developed into many various “success criteria”, and Bauman Lyons and Derby Museums decided that these could only be met by a fully collaborative “alliance” of designers, constructors and specialist contractors (including exhibition/digital specialists) appointed under the Integrated Project Insurance model

Case Study 1 described how arrangements were made to secure the acceptance of this transition by the existing consultants; how the new partners were selected; and how the alliance was formed, taking into account the hybrid “owner-controlled insurance” necessitated by the historic site.

Case Study 2 covered the progress of design, with BIM, the project culture and the alliance management and leadership, and how the gain/pain share and related insurance arrangements were concluded before work on site commenced.

This Case Study, the last in the series for this pilot project, starts by describing how the COVID 19 pandemic was addressed by the alliance, including how it affected progress. It then concentrates on the outcomes, both in terms of the finished product and also the time and cost of delivery. Success is not self-propagating unless it benefits both the client and the supply side, and insights from both are therefore also included.

The judges were particularly impressed with the project’s successful use of IPI, “blazing a trail for the themes in the government’s Construction Playbook”, with “a brave client adopting an innovative choice of procurement strategy, which has underpinned the delivery of fantastic results through true collaboration”.

The judges were particularly impressed with the project’s successful use of IPI, “blazing a trail for the themes in the government’s Construction Playbook”, with “a brave client adopting an innovative choice of procurement strategy, which has underpinned the delivery of fantastic results through true collaboration”.

To access case study 1&2:

Project summary

- 2012: Derby Museums established as an independent charity to manage sites and collections on behalf of Derby City, following closure of the Derby Industrial Museum

- 2013: creation of a prototype museum on the ground floor to test concept through an innovative “Re-make the Museum” process under public and stakeholder programme

- July 2014: Derby Museums awarded Arts Council England Major Partner Museums status

- May 2015: Heritage Lottery Fund Stage 1 approval for £9.4m

- January 2016: Arts Council England Capital funding Stage 1 approval for 2.58m, enabling 18-month development stage to begin

- March 2016: Appointment of core design team, including Leach exhibition specialists and Bauman Lyons architects who assisted Derby Museums with potential solutions which were sufficiently loosely defined to enable a fair OJEU process to follow

- May 2017: Planning submission with Conservation Plan; decision that the IPI model is to be used for this project and IPInitiatives engaged; OJEU Notice; Prequalification Questionnaire issued to applicant constructors and specialist contractors

- June 2017: RIBA Stage 3 Report: Design & Access Statement and Heritage Impact Statement; Stage 2 bid to Heritage Lottery Fund; Industry Day for bidders

- July 2017: Issue of Invitation to Tender to selected constructors and specialist contractors

- September 2017: Stage 2 Heritage Lottery Fund approval

- October 2017: Full alliance team appointed

- November 2017: Planning approval

- December 2017: Commercial alignment of alliance partners completed

- January 2018: Phase 1 design by alliance begins

- June 2018: Alliance contract (hybrid) agreed and signed

- July 2018: target completion for Phase 1

- October 2018: Inception of Owner Controlled Insurance policy for commencement of Phase 2, design development and construction

- December 2018: Late resolution of 25-year lease agreement with Derby City Council and wayleave agreement with Western Power

- January 2019: start of Phase 2

- May 2019: admission as a trial project under the Cabinet Office/Constructing Excellence Trial Projects Delivery Programme

- March – May 2020: stoppage of work due to Covid – 19

- December 2020: target completion (as extended due to wayleave issues and Covid -19)

- February 2021: actual final completion

Client objectives and vision

“There is a growing awareness in the construction sector that to improve performance key parties need to be brought together much earlier and relationships need to be significantly more collaborative. For the Museum of Making with our focus on co-operative working this is an essential transition and an innovative and new method of alliancing will suit our thinking. It is proposed therefore to use the Integrated Project Insurance (IPI) Model to deliver the project because it aligns the team’s interests and incentivises them to focus on outcomes which maximise the benefit for all stakeholders. This enables the whole team to work collaboratively under a single contract and insurance. The team form a Board under a new Alliance Contract and are incentivised to work together with all parties having a share in gain/pain that is linked to common not individual performance.”

Bauman Lyons, RIBA Stage 3 Report Rev1, June 2017

Vision

The aim was to create the Museum as a flexible, creative and inspirational hub with

technology and tools to build people’s skills, confidence and creative talent and to inspire the young creators and makers of tomorrow. The Arts & Heritage programme is to offer opportunities for audiences to participate in and enjoy contemporary art and design to creatively re-interpret the past, tell its many stories and respond to the sound of diverse voices.

Strategic Brief

The strategic brief was to create an inspirational new museum, revealing the whole building for the first time and re-introducing manufacturing to the site. It will celebrate Derby’s heritage of makers through the internationally, regionally and locally significant collections. It will create new co-working, maker and workshop spaces, with facilities for use by the makers of today and tomorrow. The project’s

overarching themes are STEAM-Powered (Science, Technology, Engineering, Arts and Maths), driven by the significance of the site, the building and the collections it contains; combined with the context of Derby and needs and motivations of local people, communities, businesses, organisations.

Success Criteria

“We have chosen the IPI model to reflect our values. Co-production and human-centred approaches are integral to the success of this project:

• Staged completion of building zones including workshop spaces at an early stage to support the build of fit out and exhibition

• Active involvement of volunteers and stakeholders in co-producing the Museum of Making

• Advocacy for new and diverse audiences

• Integrated programme of commissions for artists and makers

• Co-production and human-centred ethos, including openness to prototyping and the ability to respond proactively to change of circumstances and needs.”

–Derby Museums

The specific success criteria are numerous, falling under these headings:

Building and Exhibition: 24 No. Funders’ requirements:

- Heritage and Exhibition: 21

- People Skills: 14

- Local community: 23

Phase 2

Interruption by Covid – 19

In March 2020 the Government started to impose restrictions because of the growing impact of Covid-19 and to implement the Government’s social distancing recommendation, and the Construction Leadership Council published Site Operating Procedures, with the strong recommendation that these procedures be implemented by every operational construction site. The alliance board considered the options in close consultation with the subcontractors and suppliers working, or due to work, on site. The primary focus of the entire alliance to what was agreed to be a Review Event was to mitigate the delays and extra costs of the remaining activities as soon as the shutdown could be ended. The shutdown lasted 7 weeks; during this time the alliance made no assumption that extra funding would be available, and rather sought where significant savings could be made. The impact on the ongoing work within the constrained spaces of the Museum was monitored on an ongoing basis. Due to its cohesiveness and flexibility, the alliance gave a rapid response and agreed a target cost for the review event enabling the Heritage Lottery Fund to respond and agree additional funding – the only project to receive such a response.

Monitoring and control of costs

Refurbishment projects are notorious for cost escalation, especially where the buildings are of historic importance; the Silk Mill is at the extreme end of this spectrum. There were many stakeholders who contributed funding and whose wishes had to be respected. Derby Museums played an active part in the alliance’s deliberations throughout, and below are some of the issues which were accommodated:

- Floors: significantly more asbestos was found beyond that indicated by the survey. Instead of disturbing the ground floor to the Italian Mill, a new floor was created, saving some £170k and 8 weeks delay; also, testing, remediation, good architectural detailing and site control saved some £25k on the ground floor to the Civic Hall. Likewise load testing avoided removal of all internal floors as originally proposed, saving some £100k and 12 weeks delay.

- Rolls Royce engine: the original intention was to complete the build and install a rig hoist system to install the engine. The risks and costs of doing this were found to be extremely high: instead, the engine was flown over from America three months early to be installed, and the new Civic Hall was built around it.

- A full-time archaeologist was on site with trowel pits in various locations, around which the construction team had to work. One resulting challenge: the planned gas main route had to be diverted through the workshop to avoid disturbance.

- Flood mitigation: newly installed flood measures such as polished concrete floors and cement particle board cladding, together with a new flood alert strategy, resulted in only one day being lost to the programme despite two occasions of flooding during construction.

- The client-led co-production approach required coordinating museum staff and volunteers throughout live construction as well as supporting the museum recant. The project was re-programmed to hand over the workshop as a first element to create usable space for makers/volunteers.

- Enhanced AV display equipment was introduced as an invaluable asset to the Museum’s management plans.

- Use of refurbished furniture, more in keeping with the building.

The Rolls Royce jet engine, back airborne in Derby

Outcomes

Outcomes – quality

After nine years of initiation, consultation, prototyping, testing and sourcing the most experienced, determined and collaborative team through both procurement and behaviour workshops to deliver the construction, Derby Museums and their project stakeholders now have a conservation and restoration project of which they are truly proud, with 100% of the outlined client-led success criteria met or exceeded. In their own words:

“The project has breathed new life back into the building, revealing its scale and extent for the first time. The design of the new building was intended to reach 100% use of the existing structure, but the team delivered 110% by creating the additional floor. The look is modern with an industrial feel in quite a brutalist way with all fixtures and fittings repurposed from either the museum itself or further afield to ensure everything – including the building – is in its second use of life.”

“It has involved Derby people in the making of the museum through our active volunteer co-production programme with over 36,000 hours contributed to the project prior to lockdown, which was adapted to create remote volunteering opportunities with virtual meet-ups to reduce isolation. The Museum of Making creates access to 100% of our significant collections, provides an anchor for the city’s vision as a ‘City of Making’ (estimated to provide a gross economic impact of over £4.2m annually) and over 140,000 visitors a year will support Derby’s COVID recovery and help create new jobs. STEAM learning opportunities for schools, communities and visitors will help to continue the legacy of Derby’s heritage of ideas and innovation.”

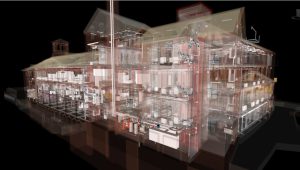

Turning to the sustainability and upkeep of the facility, Derby Museums did not have CAD management facilities. The alliance created a 3D model (see below) in Navisworks Freedom, enabling free access for Derby Museums to the model. By clicking on a specific element it hyperlinks to the O&M manual to give detailed information.

Outcomes – time

The sequence of events affecting completion can be summarised into 3 elements:

(1) Delays in signing the 25-year Wayleave agreement by Derby City Council and Western Power: after mitigation this Review Event extended the Target Date by 4 weeks and the Transition Date by 3 weeks.

(2) Delays in grappling with unexpected events and difficulties which, under the Alliance Contract (unlike traditional contracts) fall to the Alliance to overcome: these were agreed to summate to 8 weeks’ delay.

(3) Covid and its constraints on working: after the initial shutdown of 7 weeks the ongoing impacts were actively mitigated and monitored on a rolling basis; in the absence of any other intervening causes of delay, the overall impact from this Review Event was agreed as 31.6 weeks.

As actual completion was 8 weeks after the extended Transition date, pain-share was incurred and shared by the Alliance Members in accordance with the formula and proportions in the Alliance Contract.

Outcomes – cost

The Target Cost, as updated to include the above two Review Events, was £14.413m; the Final Outturn Cost was £14,867m

The overspend against the investment target was therefore some 2.8% and was funded by pain-shares in the pre-agreed proportions: the Museum bearing £63k and the partners £391k.

The credit for this achievement should go to Derby Museums, all their partners and suppliers, and not least to the supportive response of the Heritage Lottery Fund when the project was hit by Covid at its most vulnerable stage.

Other participants’ observations

As part of the model’s culture of transparency – and to inform the Cabinet Office/CE Trial Project Programme – a four-hour feedback session was held “virtually” on 27 January 2021 with the entire alliance, including all suppliers.

The feedback was thorough and forthright, and the extracts below evidence (a) the participants’ generally positive experiences of IPI but also (b) the fact that the definition of roles and the dynamics of collaboration are still developing and far from optimal.

Pandemic – the ability to mobilise as a team when the lockdown happened and also think through a comprehensive approach to writing a proposal and prediction on cost/programme for the funders was a game-changer. We know from funders we were at least 6 months ahead of everyone else – and not everyone has had the success we have.

The alliance principles [Supportive, Teamwork, Ethical, Accountable and Makers] have been included in our order and subsequently in all the orders that have been placed by us. We believe that the STEAM acronym has been adhered to and has created a team spirit and relationship that is second to none, that any of us have experienced previously. We do however believe that the people involved in the project enable the principles to flourish and that careful consideration about who we engage with and who is involved in the project is the biggest contributor to the great relationship the project team has.

I think that collaborative working is driven by a quality team and strong leadership.

This was quite an easy one for us to answer; the way the IPI model is setup up relies on collaborative planning and working. The fact that there is one cost plan and we all have equal responsibility for the project promotes synergy throughout the team. The only caveat we would add to the above is that there were sub-contractors that we have interacted with on site that still acted in the sense of a traditional contract. However, it would be difficult to mitigate this 100%.

It was really hard sometimes and those who would claim not to have made mistakes are clearly too perfect for the rest of us! I think I remember Kevin Thomas and Louise Lado-Byrnes saying that good collaboration elsewhere is in spite of the process not because of it – I agree but on traditional projects it’s easy to be collaborative when things go well – it’s when they go wrong that IPI comes into its own.

Unlike any other project I’ve ever done, I do feel like I’ve really built this one. I haven’t just designed it and helped it being built by someone else: I really feel like mentally I’ve built it. I’ve been involved in all the issues about subcontractors on site and costings and everything. It does feel much more like a group of people have come together and have created something collegially.

There may be some confusion for those new to IPI as to how the Alliance Manager is not a Contract Administrator (or where the role is similar, where it is not) – possibly worth clarifying this in IPI literature to ensure bidders correctly put forward the most suitably qualified person and to explain how a ‘no Contract Administrator’ model contributes to a more collaborative environment.

However, the role should also address how decision making, quality and change control can still be rigorously monitored under IPI if there is no Contract Administrator. There were members of the team who were not sure exactly what the role of Alliance Manager was.

I think the Alliance Cost Manager is a really difficult role in the early days when nobody is listening to reports of cost overrun. We knew this project was going to be over budget 18 months ago – as Scott and Shona were telling us that – but no-one was really taking notice at that time.

The Derby Museum of Making alliance/project has topped the Constructing Excellence East Midlands Awards 2021 for Conservation & Regeneration, People Development, Innovation, Building Project of the Year and Winner of Winners. Also winner of Construction News’ 2021 Project of the Year (under £20m) Award, joint winner of Building’s Refurbishment Project of the Year Award, winner of IStructE’s award for. Best Renovation or Heritage Project and the Derby Historic Building Trust’s Architecture award for Reuse of a historic building, and winner of the Constructing Excellence National Award 2021 for Conservation & Regeneration.

Exhibition space 2nd floor

Exhibition space 2nd floor

Hot desk office space

Hot desk office space

Exhibition space

Gallery

Gallery

Guidance on the IPI Model

Guidance on the IPI Model is complementary to this case study, and is accessible at The Integrated Project Insurance (IPI) Model.

Of particular interest will be Section 9 which identifies the benefits the IPI Model is expected to bring for:

• The Client Group

• Lead Constructor/Project Manager/Design Consultants

• Specialist Contractors

• Other supply chain members

• Insurers

• Funders

• The Local Community

For change to take off and become “Business as Usual”, there must be seen to be benefits for all parties involved.

Miscellaneous

Authors

This case study has been developed for Constructing Excellence by Martin Davis, as IPI Mentor, with invaluable assistance from his IPInitiatives colleagues Kevin Thomas (the Independent Facilitator) and Louise Lado-Byrnes (the Alliance Manager), and the members of the Alliance.

All photographs and images are by kind permission of Speller Metcalfe.

Background: Trial Projects programme

The Government Construction Strategy aims to change the relationship between clients and the entire supply chain within the industry. The trial projects perform a central role in delivering the Strategy’s sustainable reduction in costs and have been testing three new procurement models (Cost- Led Procurement; Integrated Project Insurance; Two Stage Open Book) that were proposed by industry and developed by a joint task group. Case study reports are therefore an output of monitoring the progress and outcomes of the trial projects.

They are produced at four stages: Kick-off Meeting; Brief/Term Engagement; Decision to Build; Build and Occupy. Other case study reports can be found at:

https://constructingexcellence.org.uk/cabinet-office- trial-projects/

Project contacts

For further information on Insurance Backed Alliancing under the IPI model or to introduce a potential trial project, please contact Martin Davis, IPI Mentor for the Cabinet Office, at martin.davis@ipinitiatives.com or Kevin Thomas at kevin.thomas@ipinitiatives.com or Louise Lado-Byrnes at louise.lado- byrnes@ipinitiatives.com

Successful applicants who are accepted onto the Cabinet Office’s Trial Projects Delivery Programme will then have access to the latest versions of the Procurement documentation and system, Alliance Contract, Supplier Alliance Subcontract and IPI Policy.

29 January 2022

Get involved

Constructing Excellence welcomes all organisations that share our values and mission. Get in touch to find out how your organisation can become part of the UK’s leading movement for change devoted to delivering excellence in the built environment.

Comments are closed.