Building Project of the Year

Building Project of the Year

Title: Costa – The Roastery

Organisation: Artelia

Description: Seeking to increase its roasting capacity to support its international growth ambitions, Costa’s has invested £38 million in a state-of-the-art new Roastery in Basildon. The facility’s design blends the Costa team’s 40 years’ roasting expertise, with state-of-the-art technology and robotic automation, to nurture the coffee bean from the moment it arrives to when it is packaged and shipped to its local Costa retail outlet. It also provides a central office and training hub for Costa which it has never had before, reflecting its transformation from family-run business to major part of the Whitbread empire. Costa also wanted its new facility to be one of the most sustainable industrial buildings in the world. It’s location on the new Prologis Park in Basildon was chosen for its proximity to Tilbury Docks where Costa’s raw coffee beans are shipped to. The building itself was designed and constructed to achieve BREEAM Outstanding. Sustainability initiatives include on-site renewable energy generation from a 249kw solar photovoltaic system – providing power for the roasters and hot water from the rainwater harvesting system. The Roastery represents a once in a generation investment by Costa and is central to its growth plans for the next 20-30 years. As a one-off project of considerable complexity, getting design and delivery right was critical to the client and involved Artelia co-ordinating and managing input from stakeholder groups across the Coffee business, a specialist international supply chain, as well as developer Prologis and its main contractor. Through rigorous project and cost management and collaborative teamwork, the facility was handed over on budget and on time in December 2016.

Client of the Year

Client of the Year

Title: Nwes

Organisation: Fielden + Mawson LLP

Description: We wish to nominate Nwes for the client of the year for the following reasons: Nwes are an organization that manage innovation centres many of which we have designed but not directly for them. The King’s Lynn Innovation Centre (KLIC) was the first building that they procured themselves and it was a privilege to be their architects. We were able to combine their innovation centre business knowledge with our design experience to produce a finished building that is making a difference. The initial challenges were to ensure viability and to focus on the client’s expectations. This was achieved through excellent communications, client design workshops and the approval at each key stage. John Balch and Kevin Horne were approachable, open minded and involved from start to finish.

Digital Construction Project / Initiative of the Year

Digital Construction Project / Initiative of the Year

Title: Project Capella

Organisation: Kier Construction

Description: Project Capella is a £79m research laboratory development for the University of Cambridge. The University wanted a fast-track build, and had specific criteria financially. As a result, we looked at some very fast-track methods of construction including a precast frame and precast façade panels. The solution aimed to reduce the on-site period and overlap it as much as possible with the design period. The challenge is ensuring that we maintain programme pace by understanding coordination issues comprehensively. The University was keen to use Capella as a candidate for getting processes in place and for setting up BIM protocols and how they might work. As an informed client in regards to BIM, the University is keen to make full use of the technology. The entire team is working to deliver an advanced BIM level 2. Kier was appointed at RIBA Stage 1 and implemented a BIM execution plan in collaboration with the design team, to deliver BIM via our Common Data Environment, BIMXtra. BIM was utilised heavily during the PCSA to co-ordinate the design and to programme the build. As a heavily serviced research laboratory with considerably complex and intricate M&E components, design coordination and collaboration with other trades is key. Regular coordination workshops using the progressing 3D federated model have proved highly beneficial. BIM has allowed us to identify clashes, which are then problem-solved at meetings with the design team and subcontractors, enabling the team to reach informed decisions there and then, rather than taking actions away, allowing us to maintain programme pace.

Health & Safety

Health & Safety

Title: Morgan Sindall

Organisation: Morgan Sindall

Description: Our industry covers a broad range of work, across a multitude of sectors, with a variety of complexities. This naturally changing landscape, which differs widely from one project to the next, brings with it a set of challenges setting it apart from any other industry. As one of the largest industries in the UK, with over 2 million employed, it is also one of the most hazardous in the UK. The HSE frames the challenge in stark terms stating “around one third of all workplace fatalities occur in construction, and more than 750 people having died from injuries because of construction work in the last ten years.” The HSE continues, stating that the industry has not kept pace with safety, resulting in occupational health issues also arising from construction works – around 4,500 construction workers die each year due to work related ill health. The challenge also is around skills shortages, the need for more workers and the demanding PR in the industry, all potentially impacting upon the focus on safety. So, as an industry, we face a multitude of challenges, both short and longer term, all relating to protecting the health, safety and wellbeing of the workforce. This is why, as a collaborative industry, it is important to keep positively improving the culture and performance towards safety in our industry.

Innovation

Innovation

Title: Recoup Energy Solutions – Recoup Pipe+ HE

Organisation: Recoup WWHRS

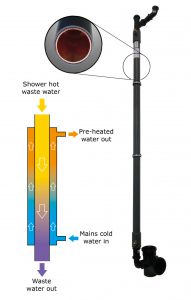

Description: Recoup WWHRS produce a range of SAP-listed, highly efficient WWHRS products, which extract waste heat energy from used shower water in order to pre-heat the incoming cold feed. This simple solution offers one of the best ‘pound for points’ ratios of any SAP measure and is a true ‘fit and forget’ product, and ultimately can save up to 50-67% of the energy cost each time a shower is used (regardless of heat source).

The Recoup Pipe+ HE is their most specified product and is also the highest scoring product in its class on the SAP 2012 database. When incorporated in new-build dwellings, WWHRS can often show SAP improvements of between 3-7% (and even up to 10% for larger properties) and therefore is one of the most cost-effective SAP measures available.

Recoup are the UK market-leader for WWHRS. They supply to many UK National housebuilders in England, Scotland and Wales, and have recently extended their Sole-Supplier Agreement with Barratt/DWH for the UK, and also supply to many other National house builders such as Redrow, Linden, Berkeley, Miller and Bovis.

The Recoup Pipe+ HE product is stocked and distributed by Travis Perkins Group, Wolseley Group and most recently Saint Gobain Building Group, so is available at over 2000 branches and therefore can dovetail with their clients existing supply chain.

Integration & Collaborative Working

Integration & Collaborative Working

Title: New Theatres, James Paget University Hospital

Organisation: Morgan Sindall

Description: Described by the Trust as the most complex project they have ever delivered, a huge challenged faced the team at the beginning of the project. Not only did the project need to be delivered absolutely on time to meet the demand of day case operations, the team had to deliver the scheme at the heart of the hospital. This meant the construction of a two storey extension on top of an existing, and live, pathology ward, whilst landlocked on either side by a live cancer ward, and live children’s ward. Business as usual, including careful linking with the main hospital services was absolutely critical. Especially made air sealing systems were installed in the cancer care ward to meet infection control requirements keeping cancer patients safe throughout the works. The team also engaged the children’s ward, bringing them beautifully made MDF animal cut outs for them to paint – over the life of the project, the hoardings separating the site from their ward, were decorated with colourful animals that the children had painted themselves, ensuring that outward views from their beds were adorned with murals of their making! Complex logistics were another huge challenge – working collaboratively with the Estates team and our supply chain partners, a huge tower crane was installed, helping to get materials safely into the site compound. One way delivery routes were set up, with off-site holding bays ensuring large loads only approached during the early or later hours of the day – outside of key blue light times.

Preservation & Rejuvination

Preservation & Rejuvination

Title: UEA Concrete Preservation

Organisation: Clancy Consulting Ltd

Description: The purpose of this refurbishment was to preserve and rejuvenate the 1960’s concrete at the UEA Campus. We provided forensic structural engineering services in the development of a fiveyear concrete preservation plan, waterproofing, drainage designs and detailed repair specifications. The work also included improvements to the safety of the high-level walkways to decrease the potential for falls from the relatively low balustrades. In 1962, Denys Lasdun was appointed by the University of East Anglia as their founding Architect and designed the core buildings including the Teaching Wall, the raised walkways, Central Square and the ‘ziggurats’ of the Norfolk and Suffolk Terraces, with exposed fair-faced concrete as the principal structural material. The terraces are of cross wall construction with many of the structural walls and external panels created from precast concrete panels formed on site. The teaching wall walkways are constructed from cast in-situ concrete. A big challenge was that the buildings were granted Grade 2/2* status, but in common with much of the concrete building stock in this country from the 1960’s the material has suffered from varying degrees of weathering and deterioration over the years. This could be seen with spalling to the concrete surfaces and rust staining from corroding reinforcement. Another major challenge was to understand their structural form so that adjustments could be made to the protective barriers around the walkways. We were commissioned by the UEA from 2011 to develop a five-year plan for the rejuvenation and preservation of the concrete.

SME of the Year

SME of the Year

Title: RDT Architects – Specialist Dementia Care

Organisation: RDT Architects

Description: RDT Architects have dedicated Planning and Construction Teams providing innovational design and construction solutions for clients in all sectors with a focus on creating excellent care homes. RDT have a passion for the care sector, having completed numerous new build dementia care home schemes and are fast becoming recognised for our planning successes and design skills within this niche sector. We work closely with end users, operators and delivery teams, advising on areas outside the brief and adding value and benefit to the client, residents and staff. This submission demonstrates RDT’s commitment to delivering specialist dementia care homes and how we work alongside care home operators to achieve award winning dementia care designs which meet the criteria of the client, end user, staff and visitors whilst maintaining a homely and safe environment. It focuses on dementia care home design for not-for-profit operator Quantum Care Limited and will outline the time and dedication afforded by RDT to develop a dementia care home design strategy above and beyond the needs of our client and catering for the increasing number of people with dementia. Quantum Care undertake extensive research to identify the needs of their customers and regulators to ensure new care home design meets current and future demands in an ever changing care market and RDT Architects are key to achieving this aim. Research shows a significant increase in the prevalence of dementia in the 65+ age group rising by 46% by 2025, demonstrating a clear demand for this type of care.

Sustainability

Sustainability

Title: Fabric First Institute Project

Organisation: Whole House Energy

Description: Energy policy over the coming years will challenge the construction industry to deliver more energy efficient building stock. To do so with increased effectiveness is going to be key to business profitability, housing affordability and energy efficiency. With £47 million of construction work and 1000’s of new Passivhaus standard dwellings committed to by Norwich City Council over the next 3 years, an enormous opportunity has presented itself in the region through the Norwich City Council’s Fabric First Framework. To deliver these developments effectively wide-scale up-skilling was needed to ensure that the ‘silo-mentality’, currently rampant within the construction industry, and largely held accountable for the ‘Energy Performance Gap’, was eradicated. This needed an innovative approach to training, bringing together specialist knowledge of a number of areas (airtightness, thermal bridging, mechanical ventilation systems), simultaneously delivered to all construction trades. In response to this, through a match-funded grant from the New Anglia Skills Deal Programme, provided by Norfolk County Council, Suffolk local authorities and the Skills Funding Agency, the Fabric First Institute (FFI) project has been developed. It aims to act as a catalyst for a step-change in construction practices both regionally and nationally. Working collaboratively with regional partners from the construction, manufacturing and low energy sectors, educational establishments and local authorities, it aims to impact current construction practices to bring about change. It is up-skilling both the workforce and students through development and delivery of a training programme and City and Guilds Level 3 Accredited module.

Value Award

Value Award

Title: Costa – The Roastery

Organisation: Artelia

Description: Seeking to increase its roasting capacity to support its international growth ambitions, Costa’s has invested £38 million in a state-of-the-art new Roastery in Basildon. The facility’s design blends the Costa team’s 40 years’ roasting expertise, with state-of-the-art technology and robotic automation, to nurture the coffee bean from the moment it arrives to when it is packaged and shipped to its local Costa retail outlet. It also provides a central office and training hub for Costa which it has never had before, reflecting its transformation from family-run business to major part of the Whitbread empire. Costa also wanted its new facility to be one of the most sustainable industrial buildings in the world. It’s location on the new Prologis Park in Basildon was chosen for its proximity to Tilbury Docks where Costa’s raw coffee beans are shipped to. The building itself was designed and constructed to achieve BREEAM Outstanding. Sustainability initiatives include on-site renewable energy generation from a 249kw solar photovoltaic system – providing power for the roasters and hot water from the rainwater harvesting system. The Roastery represents a once in a generation investment by Costa and is central to its growth plans for the next 20-30 years. As a one-off project of considerable complexity, getting design and delivery right was critical to the client and involved Artelia co-ordinating and managing input from stakeholder groups across the Coffee business, a specialist international supply chain, as well as developer Prologis and its main contractor. Through rigorous project and cost management and collaborative teamwork, the facility was handed over on budget and on time in December 2016.

Young Achiever of the Year

Young Achiever of the Year

Name: James Bussey

Organisation: Hudson Architects

Description: James Bussey is a young Norwich-based ‘starchitect’ who, in December 2016, beat worldwide competition to win a Royal Institute of British Architects (RIBA) President’s Medal Award. These awards were established in 1836 to reward young architectural talent, promote innovation and encourage excellence in the study of architecture worldwide. James beat off extremely tough competition, with 130 entries received from 320 universities and 65 countries. James won an award for The Company – a project completed while studying at the University of Kent (where he had already gained a first glass honours degree and later completed a Masters of Architecture with Distinction). James’s winning project represented a series of drawings – plans, sections and isometric drawings – in the form of a graphic novel. He was picked out by the judges for his exceptional drawing skills, becoming the first student from his university to win a RIBA President’s Medal award. James has worked at Hudson Architects since September 2015. One of his objectives in preparing The Company was to break down the complexity of the project and make it more accessible to a public, non-architectural audience. He applies the same approach to his own work at Hudson Architects, where he is leading efforts within the practice to implement new ways of working, in particular providing simple visual material that helps clients and project partners understand a project more clearly. In his spare time James is exploring how new technology can help architects and clients create better buildings through harnessing virtual reality (VR) technology.