Estimating the capital costs of a building project is a well understood process – but what about predicting the maintenance costs and the resources needed during the operational phase? As the industry begins to digest BIM process theory, case-studies that prove new concepts (such as practical methods of using BIM within the building operational phase), are still rare, and therefore are highly sought after. Motivated by this, One Creative Environments Ltd. (One) undertook an R&D project with BESA to define a workflow which enables usable data to be automatically extracted from BIM for real-life benefits in FM.

This innovation stands out from the crowd as it provides a practical step-by-step method of applying minimal additional effort to extract extremely valuable usable information at building handover for clients/operators and the results of the project have already been shared widely with industry, free of charge. It can be applied to any project using BIM, and the results of our findings are available to be implemented by anyone wishing to deliver tangible benefits for clients.

At Government Level, Building Information Modelling (BIM) Level 2 has been mandated to target savings of up to 20% across the design, construction and operational phases of a built asset’s lifecycle. The majority of expenditure, we know is within the operational phase and decisions taken in the design and construction stage have the biggest influence on the operational costs and efficiency throughout the project lifecycle.

We therefore believe that clients should have visibility of the operation and maintenance costs earlier in the design process, so operational decisions can be a key part of the decision-making process during the design and construction phases. The challenge was ‘in reality, how can this be done’? Could BIM unlock the TOT-EX concept? Our R&D project delivered a practical method of implementing the savings and efficiencies promised by emerging digital construction technology hype.

One is continually looking to explore, innovate and leverage BIM technology. Working with BESA and Northumbria University, One defined a new BIM workflow that allows operators to extract accurate maintenance costs/schedules and the resources needed to maintain assets, directly from models.

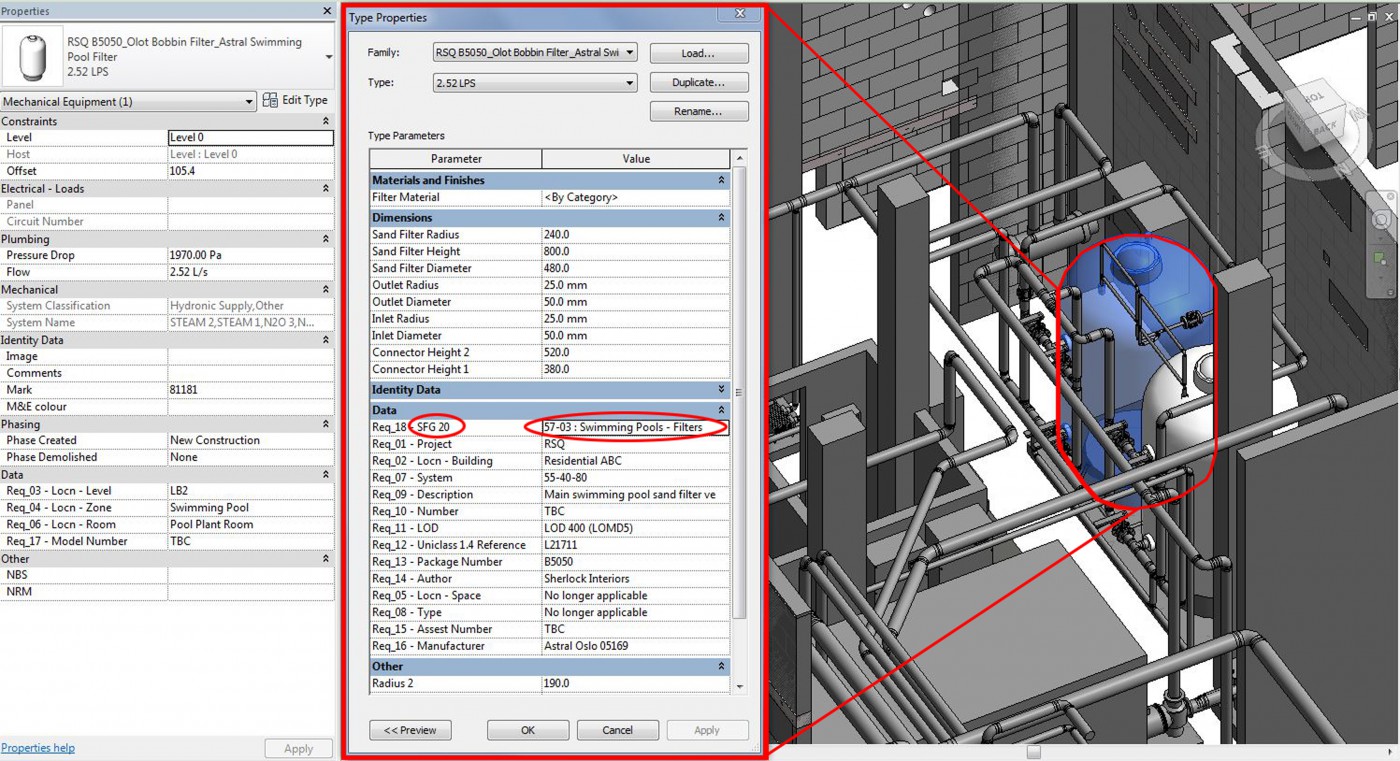

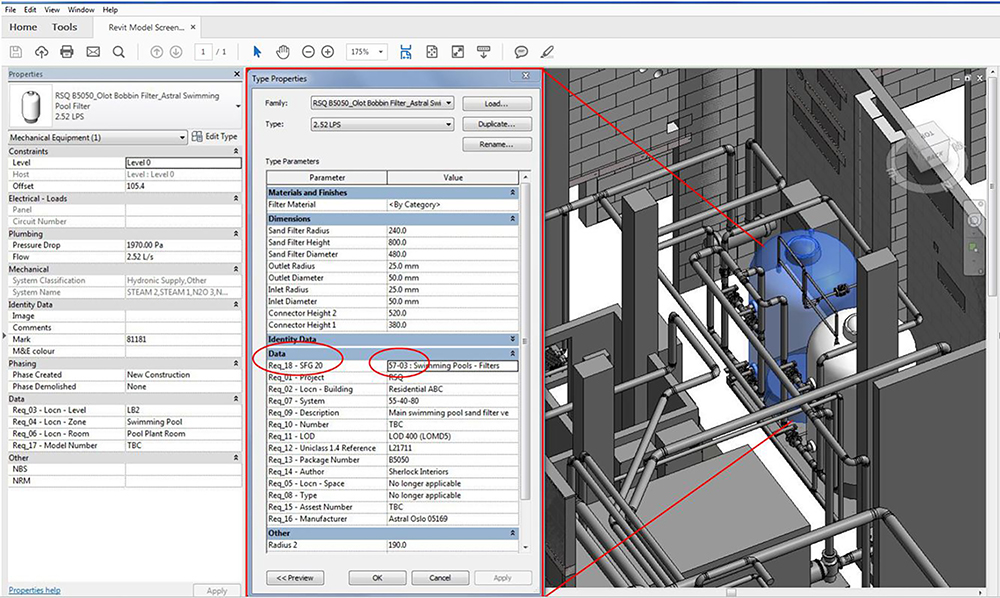

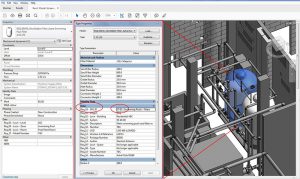

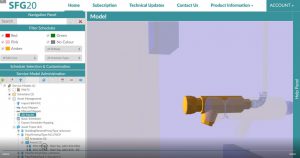

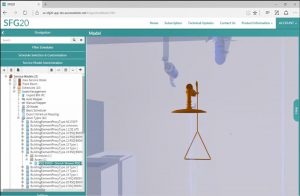

Using SFG20 codes (the established industry standard maintenance specification for building engineering services and an essential tool for planned maintenance), an efficient way of adding specific metadata into BIM was found to enable Planned Preventative Maintenance (PPM) Schedules to be extracted directly from the model without manual manipulation/remapping. This allows clients to understand their asset’s maintenance requirements, predict operational lifecycle costs, and develop efficient maintenance programmes well in advance of building handover. In addition, at building handover it also provides the building owner with a fully populated PPM schedule that maps out what needs to be maintained, when, and by which type of resource. This innovation has the potential to save clients tens / hundreds of thousands of pounds on each project and unlocks the power of BIM to truly drive cost savings into the operational phases of building projects.

Key achievements

- This R and D project provides a practical, simple method of achieving the aspirational statement heard through the industry that “BIM data can be used to save money in building operational phases” – this method provides a practical workflow which is simple and repeatable.

- Through the implementation of this simple process, as proven through this R&D project, clients will save tens / hundreds of thousands of pounds on each project.

- By having better information on asset maintenance earlier in the project, clients can use the information to make better decisions earlier in the design process, to help plan for building handover and maintenance, and predict the cost of doing so.