The current COVID situation is forcing everyone to live and work differently. We are embracing new technologies and ways of working. This applies across all areas and levels of construction from design teams through to delivery on site, we are all embracing change. But what impact is this having on productivity? Are we more productive? Are there positives that will be taken forward into the ‘new normal’? Could this accelerate our much needed transformation towards being a more productive sector?

These are some of the issues we explored with John McGovern, chair of our Performance Measurement Forum and Head of Asset Investment at Northumbrian Water Group. We had contributions our newest members Patrick Scannell, Buildots and Ian Bayes, Logikal with examples of how COVID19 is impacting on productivity in the sector.

As Patrick said, ‘When the government initially imposed lockdown measures on the entire country, we were all preparing for a sharp and immediate decline in productivity – which is most certainly what happened. With furloughing, people being let go, staff working from home, the entire industry was met with a gut punching drop in productivity.’

Causes for the drop in productivity include supply chain disruption, social distancing measures, furloughing of staff, working from home guidelines all contributed. On sites we saw the number of staff decline by around 50% so physical work was obviously hit hard too. There is too much uncertainty right now to understand what the future will hold. Different projects may take longer to recover progress.

Three things, close to Constructing Excellence raison d’être emerged:

- Collaboration is key

- Support for supply chain

- Adopting digital technologies

Collaboration is a key enabler. The issue of measuring collaboration and behaviours was discussed and will be drilled into further at the next Performance Measurement Forum in the autumn.

The client’s perspective

John McGovern, Northumbrian Water Group and Chair of the Constructing Excellence Performance Measurement Group reinforced the need to take a data driven approach to industry transformation.

As an essential service Northumbrian Water (NWG) had to find ways of continuing to deliver their projects through the crisis. They closed their collaborative office and 250 people began to work from home. Sites were made safe in line with social distancing guidance and ‘essential work’ was prioritised. NWG objectives were to maintain outputs and affordability, rebuild productivity and efficient execution of projects so they could emerge stronger in the future and support the long-term sustainability of the supply chain.

A COVID19 working group was established with daily calls in place and subgroups looking at Health, Safety & Wellbeing, Commercial, Maintaining Supplies and Maintaining Productivity. All partners and their supply chain adapted their safe system of works to comply with COVID 19 and updated risk assessments. Maintaining a 2m distance in the workplace requirement meant projects, tasks and control documents were continually reviewed. Pedestrian access routes were widened with passing points installed. The key point was ensuring that the message was simple, clear and visible.

Future control measures include signage to explain the essential nature of the works to the public and development of a common engagement document for all partners engaging externally. Engaging with design managers to ensure designers/architects are made aware of restrictions and plan / engineer control measures into designs to accommodate social distancing. Manufacturing-led approaches such as more off-site fabrication of pipework, use of precast products and longer pipework are viewed as key enablers of being able to distance people.

NWG have implemented an action plan focussed on maintaining productivity with themes including working from home, managing delays / optimising schedules and remobilisation. NWG is very much focussed on working with the supply chain to manage risk, including looking at known and unknown risks to support pricing and allocation for new contracts and data capture processes in place for all schemes. In future NWG will look at opportunities for long term future benefit such as programme level pain / gain mechanism, rather than project level.

In general, no major supply chain issues have been encountered. The situation has improved daily with increased number of suppliers getting back to business as usual. This is mirrored internationally with many companies emerging from lockdown restrictions. Supplier engagement is key to future success

and ensuring they are in a strong financial position, measures have included improved payment processes and better order management. In future this will include engaging with key suppliers around their current financial position and order book, measures taken i.e. any changes to business model, what provisions they have in place should second wave materialise, what the framework partners could do to support and secure supply if second wave hits.

Collaborative Procurement

The pandemic has strengthened collaboration and work is ongoing with partners to devise a strategy for collaborative procurement. Currently NWG are collecting data with each partner providing details of agreements they have in place and durations etc. Any commonalities will be reviewed and potentially identified as quick wins where volumes could be aggregated to secure better pricing.

Establishing a robust demand forecast is essential. Full visibility of NWG Programme of Works will greatly assist when devising risk reduction strategies with supply chain. Entering into D&C Contracts as soon as possible to allow key kit and plant to be ordered in good time ensuring float in the programme. Potential to advance order high risk, critical equipment and store/vest to reduce risk but some form of project surety is required.

Strong Supply Chain Relationship Key. Where a number of contractors have experienced difficulties with supply the impact for NWL has been minimal. This highlights the importance of having a strong robust supply chain with good relationships. NWL and its partners should continue to invest in supply chain relations and initiatives such as GEM awards and Tier 2 supply chain workshops, have all helped build trust and loyalty where suppliers are more likely to support us in difficult circumstances.

Project Management Perspective

Ian Bayes from LogiKal, an international project management consultancy that specialises in developing and delivering digitally integrated project controls solutions provided a project controls perspective. LogiKal have been working with clients to support client teams to review the impact COVID19 has had on schedules and overall productivity, particularly on scope, cost and programme.

LogiKal’s global survey of project controls has identified trends in the uptake of solutions that can support greater productivity. They have found that:

- Projects with system integration and fully integrated project controls are twice as successful than project systems that operate in silos.

- Projects that implement and engage project controls at bid stage or concept stage are seeing 52% higher success rates.

- Projects with Level 3 BIM maturity are more likely to achieve project success.

Integrated project controls have provided projects with an accepted and accurate project baseline, the ability to run detailed scenario modelling to remobilise and accurate data to identify and record the impact of COVID-19. Conversely without integrated controls there is limited linkage between cost and schedule, limited data to understand the impact to productivity and greater uncertainty.

Factors such as less staff on site, new Social Distancing requirements and supply chain disruption have impacted productivity. Welfare of staff has to be the number one priority. The impact on programmes is uncertain as new output levels are unclear and cost estimates are difficult as they are traditionally based on historical rates of productivity. Ian highlights the need to integrate cost and programme to provide future cost certainty and collaborative scenario modelling to determine key milestones and budgets for cost to complete.

Ian highlights the role that digital technologies can play in determining new productivity levels including 4D planning, quantitative risk schedules using P50 and P80 approaches to determining milestones, assuming a 20-30% drop in productivity. Logikal are investigating how short term and medium term reductions in productivity could impact project outcomes’

Technology Perspective

Patrick Scannell from Buildots provided an overview of how construction technology can support productivity. Buildots uses hardhat-mounted 360-degree cameras that capture construction site images that are then overlaid with the 3D model to form a continuously updated, always accurate, digital twin. The AI analyses every aspect of progress on site, providing vital data to the management team to increase efficiency.

The shift to a more flexible work environment is well underway. Tech giants have led the charge, and many companies in the construction industry are going to have to adapt too. There needs to be an acceptance that less hands on staff are going to be working from home a couple of days a month from now on and there are job roles that, with the right level of technology, can be done at home just as effectively as in the site office.

With this going forward, Buildots have used this massively disruptive time to dig into the analytics of how Buildots is used, who’s using it, and how frequently. Buildots are now actively looking for trends in their analytics data and are seeing massive spikes in usage. In the first 4 weeks of lockdown clicks per user went up by 60% compared to the 4 weeks before lockdown. Usage increased for both on site staff as well as those working from home. Those working from home have become quite dependent on Buildots to perform their daily tasks. A 30-minute capture by a member of the site team allows the entire project team to be able to work on their daily tasks without being on site.

Buildots attribute the increase in usage to the fact that the whole project team still need visibility of their area of work. For example, the 68% increase in use of the explorer tab is because there are more people working remotely who want to see the physical progress of their project. The data showed which job roles were suffering more than others and it became quite clear that Commercial Managers were having a tougher time doing their regular tasks while working from home. Buildots accelerated the launch of their new commercial feature, that was specific to the CM/QS’s by 2 months. The software allowed commercial managers tasks to be done more quickly and efficiently, thus freeing up their time for more important tasks. This has ensured their productivity while working from home was at least equal if not better than their productivity on site. The tab gives precise completion %’s based off the BIM model and the images that are analysed by their deep learning AI. For example, if a drylining subcontractor said they had completed drylining on a particular floor, it is now very easy to verify that in fact, no, they’ve completed (as an example) 94% of drylining for that particular floor. This is objective, non-biased, and factual

Interestingly now that main contractors are going back to site with their full staff, Buildots usage has increased even more, making their jobs more effective and efficient in the process. Buildots are keen to ensure the habits that teams formed during lockdown will continue when they’re back on site. The commercial aspect is just a small part of the package but is the one that correlates mostly with maintaining productivity during a lockdown.

There are very few positives to take from this pandemic, but the shift towards tech adoption in the wider industry must be one of them. If we can prove how the technology has helped people become more productive during this time, then these are things they need to be carrying on doing once we get back to normal.

Discussions and participant feedback

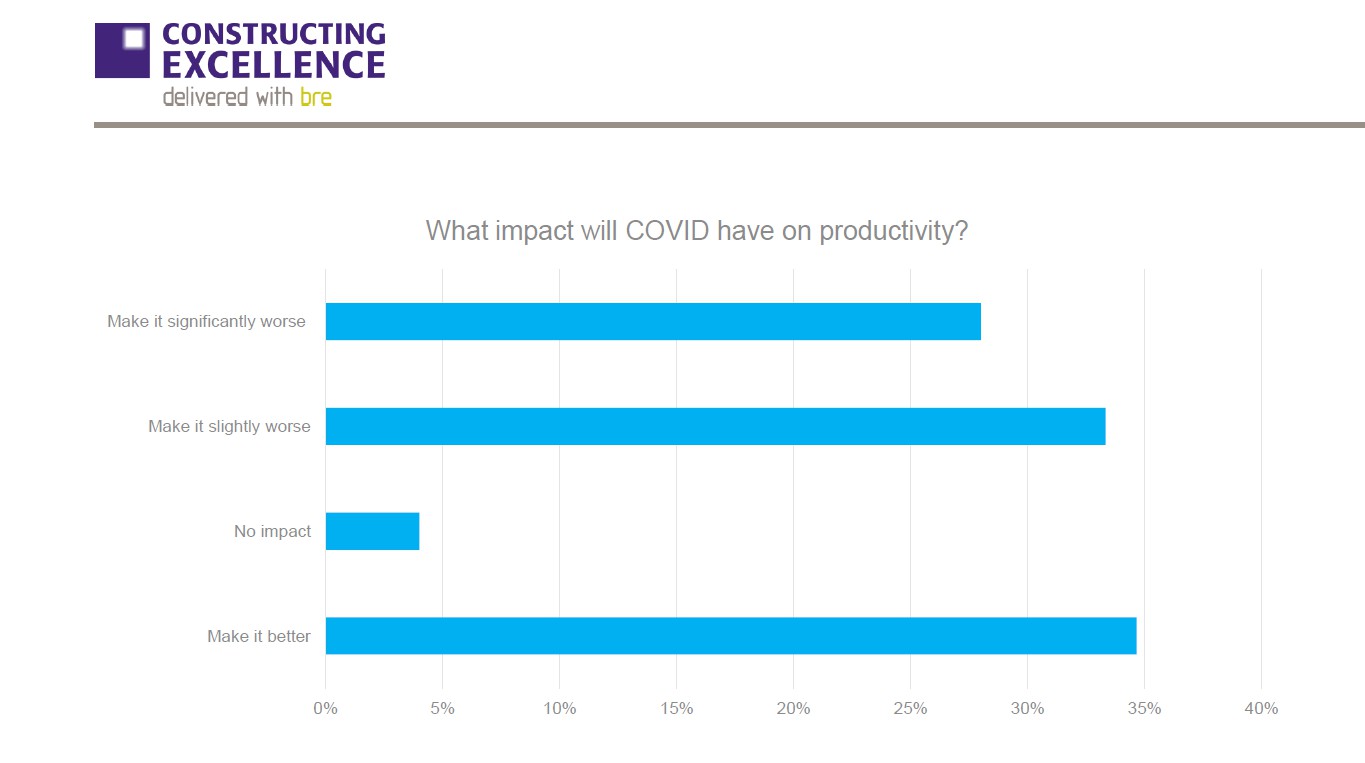

Delegates were asked in advance what impact COVID would have on productivity. Most were pessimistic about the future impact on productivity.

Amongst the negative impacts participants listed the following:

- Costly

- Slow

- Slow in transition

- Project delays

- Uncertain pipeline

- Supply chain disruption

- Adverse impact on SMEs

- Potential reduction in design productivity

- Risk of attitudes towards compliance

- Revert to how we’ve always done it

- Reduction in demand across the sector

- Over capacity

- Longer schedules due to social distancing

- Big challenges in the fit-out sector

- It’s a major disruption in a very fragmented, non process driven economy

However, many saw opportunity including:

- MMC adoption

- Trust

- Empowerment of staff

- Openness to new ways of working

- Digital Tools

- Streamlined back office

- Less people on site

- Digital twins making project planning and planning for social distancing easier

- Less time spent travelling

- Technology and automation

- Streamlined processes

- Potential manufacturer driven approach to project delivery

- Implementation of proper project management controls and tracking of productivity

- Planning and execution

- Speed up decision making

- Less distractions on site

- Work / life balance

Participants equally looked to the following enablers of long-term producitivity:

- Clients need to act responsibly particularly towards SMEs

- Collaborative approach to contracts and procurement

- Support from government for adoption of MMC

- Need to invest in digital tools and training

- Staff will need a lot of support in the transition

- Need to focus on procurement, contracts and data

- Need to examine supply chain more closely

- BIM as an enabler

- Need to re-think the entire work process

- Need to embed many of the habits of working when people are working in new normal

- Need to remember each site is different and will have its own nuances and factors impacting productivity

Comments are closed.