The site posed significant challenges with a retained 1830’s Grade 2* Listed Portico and preserved basement structures included in the new scheme. To retain the listed Portico and its basements we needed to install additional façade retention supports and shoring structures across the sites footprint. The adjacent Grosvenor building required underpinning of its foundations to

ensure its structural stability without impacting upon the Portico. With reduced academic space the University had a strong desire to stay in the adjacent Grosvenor building and required unfettered access for staff, students, deliveries, refuse collection and maintenance. Numerous services ran across the site serving the University, local businesses and other important local infrastructure. Oxford Road bounded the site containing live services including primary routes for gas, LV and HV electric, water, fibre-optic broadband, traffic signal controls and lighting.

These further constraints required careful consideration, design co-ordination and sequencing to ensure they were maintained. Combining the above with a prominent city centre location, high volumes of pedestrian, cycle and bus movements, permanent arterial road closures adjacent to site, live university buildings bounding 3 elevations and works to surrounding buildings running

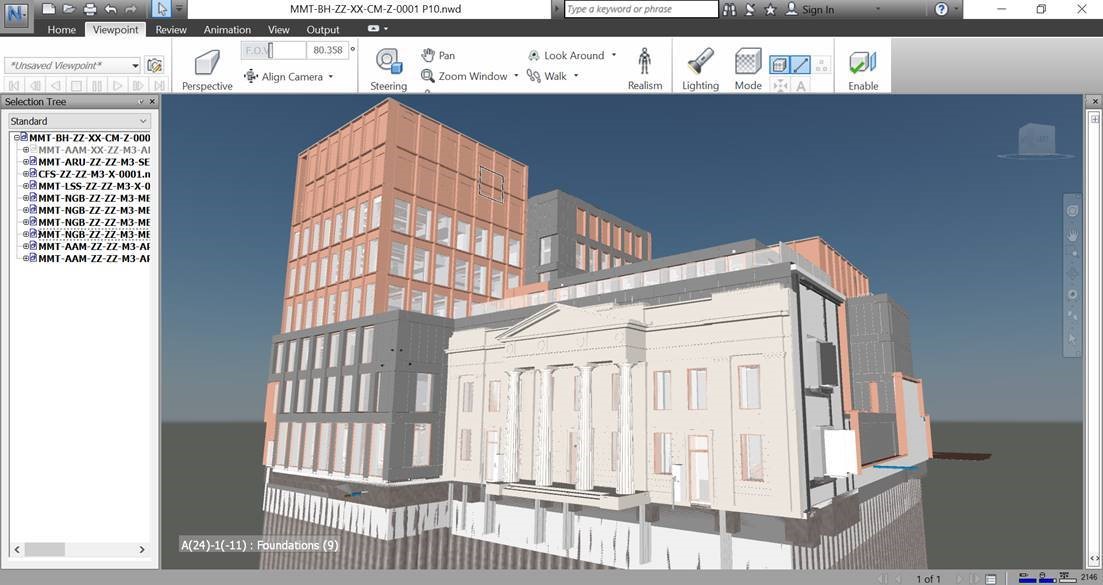

concurrently, all resulted in significant logistical challenges. The constrained site created immense programme and sequencing constraints and demanded strict design co-ordination and complex sequencing. We explored innovative design solutions leading to the development of pre-fabricated elements. We also used digital information in a variety of forms allowing Morgan Sindall to develop the right solutions, deployed quickly, whilst maintaining the clients brief through regular stakeholder engagement.

Client’s Team MMU’s BIM Manager, Turner&Townsend, developed the EIR’s reflecting their BIM requirements. Our Information Manager, BakerHicks, conducted Quality Assurance Reviews validating BIM information accorded with the BEP highlighting any actions to the principal and supply chain designers. Our BEP proposed EDocuments to collate O&M’s providing access to MMUs Facilities Management (FM) platform, Springboard. MMU’s PlanOn

FM system links with Springboard providing seamless data transition. We tested the design and client changes with MMU using models and visualisations to gain early agreement including working with the Estates team to establish how the complex façade and multi-level roofs could be accessed and maintained. MMU and T&T gained transparent access to our programme where

‘Visual 4D Planning’ demonstrated planned v actual by linking programmes to models. Designers The designers led by Allies & Morrison benefited from Bond Bryan’s support bolstering their BIM capability providing BIM upskilling opportunities. Arup created multidisciplinary models including structure and existing and new services ensuring complex interfaces could be resolved. Planning / Highways Models were used to speed approvals with Highways and Local Authority Planners including façade retention signage. Supply Chain Our

supply chain created detailed models, especially MEP, steelwork & catering, enabling the early decision to prefabricate corridor and riser MEP modules resulting in an 8 week saving. Public We installed an electronic information point outside our site providing the public with contemporary information including progress, planned work and a model walkthrough. We also used models to induct visitors so they understood what was happening on site.

Key achievements

- Hackitt’s Golden Thread. Hackitt’s Report brought fire safety and regulatory compliance into stark focus for high-rise buildings calling for a ‘Golden Thread of Information’ for every building. This thread would manifest in a single repository of information for buildings, a ‘Digital Twin’. MMU’s building, whilst not high-rise, benefited from the generation and collation of a record of what was built, the digital O&M’s. The ‘Golden Thread’ is captured within the O&M’s including, point cloud survey, federated models enriched with asset data and

3600 digital images capturing envelope and fitout activities. Creating a set of digital O&Ms provided MMU with accessible asset data which can be integrated with their CAFM system allowing the maintenance of the ‘Golden Thread’ through occupation as Hackitt suggested. O&Ms are used to manage and maintain the building and when modifications and repairs are required, the model in conjunction with 3600 images can be used to plan works virtually with

certainty, which is missing from many existing buildings. With certainty gained from reliable asset information these risks can be minimised or eliminated and MMU’s students, staff and visitors appreciating that digital construction contributes to their continued safe enjoyment of their new building. - Resolving Constraints. The constraints outlined above often created conflicting demands on the project requiring complex solutions developed using digital construction techniques including 4D and VR visualisations both derived from the federated model, the ‘digital twin’. Using these techniques allowed us to share complex ideas in forms easily understood by MMU enabling agreement to be gained quickly which otherwise would have relied upon extensive engagement, potentially delaying project commencement. Our collaborative engagement approach ensured the soft landings process was effective e.g. by engaging MMU’s Estates team early to drive the design ensuring it wasn’t just aesthetic and functional but easy to operate and maintain. This approach reaped unforeseen benefits during Covid lockdown when we had already gained significant buy-in from Estates and FM teams on the operation and maintenance of the building enabling a streamlined handover process.

- Covid. Covid’s lockdown brought many new constraints to the project approaching completion providing new challenges. Layers of digital information already existed from 2 years of BIM modelling, design co-ordination, clash detection, links to 4D models and a project team now well-versed in harnessing the benefits of digital construction. This enabled the site team, using the models, to virtually plan and test new ways of working including creating one-way systems and passing zones and reconfiguring site accommodation. It was this work, shared with and adopted by the Construction Leadership Council that helped to maintain progress closer to pre-lockdown levels than many others in our industry without compromising the health and safety of people on site. Adopting a digital approach to commissioning, holding testing, training and witnessing sessions over Microsoft Teams gave the client’s team the confidence that handover could be safely achieved. These ‘Teams’ sessions are embedded in our O&Ms and will inevitably contribute to future handover processes.