Greatfields Zone 2 is an outstanding project, taking the excellent delivery of Greatfelds Zone 1 school and improving every aspect to deliver a better outcome second time around.

The first £4.5m phase was delivered in 2017 to accommodate a brand-new secondary school in Barking. The second £9m phase was delivered in 2019 to accommodate the continued growth of the school.

The Mid Group and the client, LB Barking & Dagenham have collaborated to ensure the outcomes for the second phase exceeded the first. To do this, the first meeting on the second phase was a lessons’ learnt based on the outcomes of phase 1, hosted by an external consultant, Currie & Brown. This session involved a wide range of stakeholders, including:

- End-user school;

- Borough;

- Architects;

- Engineers; and

- Key subcontractors.

This session was used to identify what went well and what could be improved. This frank session was highly rewarding for all and set the Project up for success.

The Borough committed to an innovative procurement approach, with all parties who engaged with the lessons’ learnt session being given the guarantee of the same role on the Zone 2 project, as long as they were able to deliver to the same price (effectively 5% continuous improvement as 2 years later) and factor the lessons’ learnt into their work.

Without exception, all parties signed up to doing so.

The outcomes included:

- Delivery for the same £/m2 as the project delivered 2 years earlier.

- A programme saving of 3 months over the first phase.

- An AFR of 0.0.

- Constructed to Net Nil Carbon.

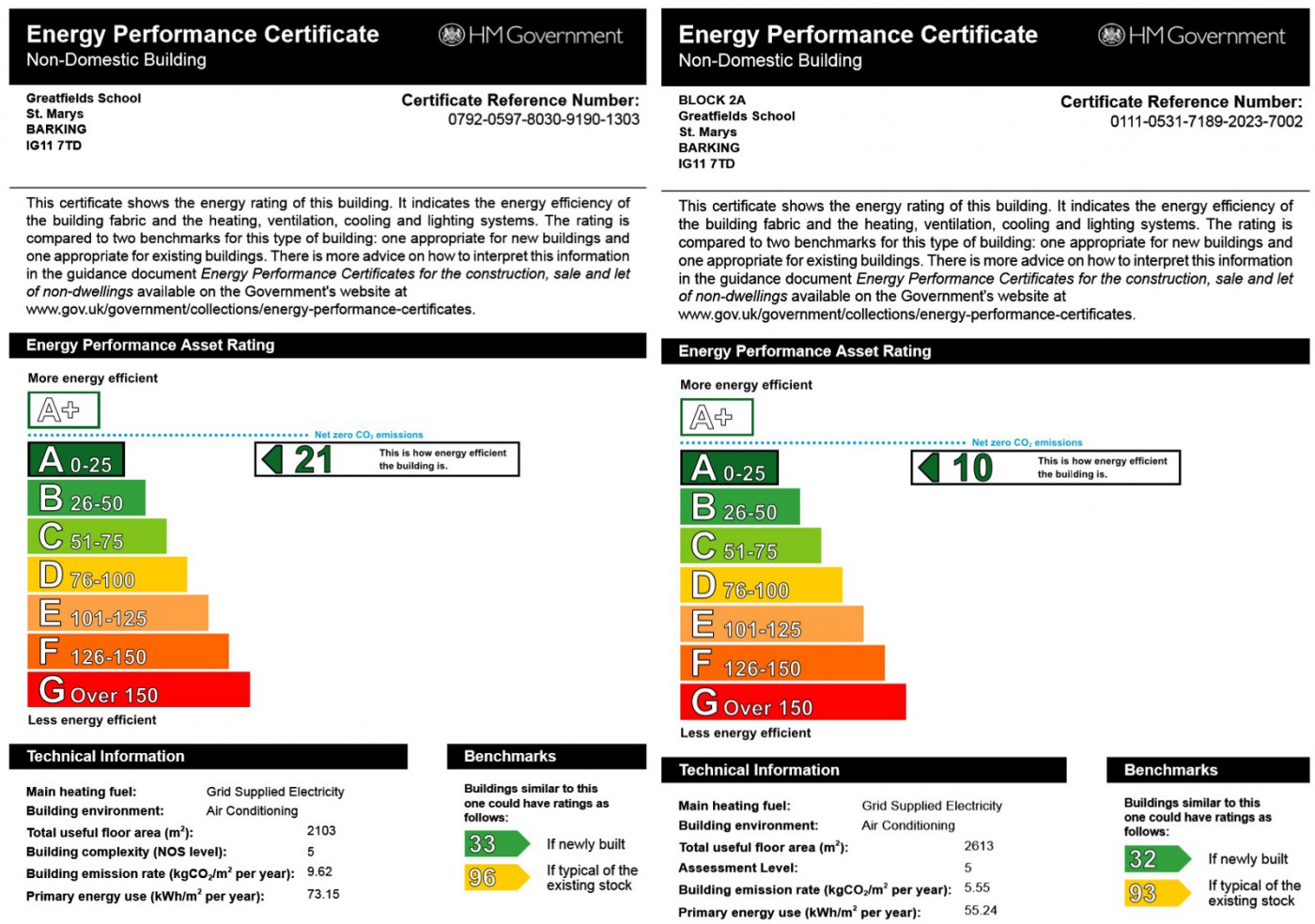

- An improvement in energy usage from 73.15/m2/yr to 55.24/ m2/yr. This is a 27% saving against anticipated rates, which will reduce energy bills by a commensurate amount, which immediately feeds back into the school’s budget.

- An improvement in building emission rates from 9.62 kgCO2/m2/yr to an outstanding 5.55 kgCO2/m2/yr.

- An improvement the EPC score of 21 down to 10 (the lowest the assessor had seen for a fully air-conditioned building, essential to future proof the school against climate change).

- Over 75% of the project value being delivered using offsite solutions, a 10% increase on Zone 1.

The project has been construction using Mid Group’s Manufacturing Led Construction approach, which involved an innovative hybrid offsite solution of SIPs and Precast Concrete. The approach also reduced waste on site, with only 1 tonne of waste sent to landfill.

The project has been delivered using 16 manufacture components, that have been repetitively repeated throughout the construction process. The components are all BIM modelled, with full cost, programme and lifecycle data.

The Greatfields School is extraordinarily sustainable not only in its construction, but also in its design. The use of exposed precast concreted soffits allows the thermal mass to assist in heating and cooling. It also allows the windows to reach the full height of the soffit, improving natural daylight and reducing reliance on artificial lighting.

Key Achievements

- Greatfields Zone 2 shows exceptional continuous improvement over Zone 1, at no additional cost.

- The outcome achieved is exceptional regardless of budget, but this was within a DfE budget.

- The achievements were not Mid Group’s alone, they were the product of collaborative working between the client, contractor and supply chain.