Trial project:

Dudley College Institute of Transformational Technologies

New delivery model/ procurement route:

Integrated Project Insurance

Key Specific Objectives

- Predictability of completion at a cost which is below the agreed Target Cost

- Build quality to give an exemplar to learners and staff, with a high-quality learning environment that inspires

- ‘Function over form’ to ensure the best possible facility for training within the investment target and the maximum possible delivery space is achieved within the envelope

- Highly efficient methods, including off-site manufacturing and new methods of construction are considered in the design and delivery of IoTT eliminating waste in materials, processes and procedures

- It should create 20 apprentice positions and a live training environment for the college and its partners as part of its construction

- The IoTT is required to achieve an EPC A rating.

Download pdf: Dudley College Case Study 3

For Case Study 1 & 2, see: Integrated Project Insurance Case Study – Dudley College IOTT – Constructing Excellence

| Trial report sequence: | Kick off meeting | Brief / Team Engagement | Decision to Build | Build and Occupy |

| Cost saving basis: | Investment Target | Challenging cost target | Agreed Target Cost | Outturn Cost |

Key facts

| Project title | Institute of Transformational Technologies |

| Clients | Dudley College |

| Overall project value (revised) | £23.1m including land, equipment & fittings and VAT |

| Investment Target (capital cost) | £17.36m |

| Form of project | New build educational facility |

| Independent facilitation and risk assurance | IPInitiatives

Technical: Building Life Plans Financial: Rider Levett Bucknall |

| Alliance Members | Dudley College

Cullinan Studio: architects GCA (UK): structural and civil engineers Cundall: multi-disciplinary engineers Fulcro: digital co-ordination Speller Metcalfe Malvern: constructor Derry: building services specialist |

| IPI Brokers | Marsh |

| Key Suppliers in Phase 1 | Traditional Structures: steel frame MSW UK Ltd: structural floors

Uponor Ltd: TABS System (heating & cooling) BC (Roofing Contractors) Ltd: external cladding Dunton Environmental: ground remediation Walsh Construction Ltd: groundworks All Glass Systems Ltd: windows & curtain walling Monarch Roofing Co.: roof system Planet Partitioning: glazed partitions Roskel Contracts Ltd: drylining |

| Other key suppliers | Hadley Group: steel frame system Independent Scaffolding: scaffolding LCS Mechanical: mechanical labour

Monarch Electrical Contractors Ltd: electrical labour H&G Carpentry: carpentry & joinery Interior Décor Ltd: painting and decorating Gladston Carpets & Flooring Ltd: flooring Jack Moody LCE Ltd: Landscaping |

Executive summary

This Institute of Transformational Technologies (“IoTT”) facility is the second project to be procured and delivered on behalf of Dudley College under the Integrated Project Insurance model which applies an integrated collaborative working approach throughout to a level which exceeds any other previous procurement routes the College has used. It requires the adoption of a Project Bank Account, BIM, and lean design and implementation practices. Via IPI the College seeks to achieve cost, time and carbon savings in line with the “Government Industrial Strategy: Construction 2025”.

Guidance on the IPI model was published by the Cabinet Office in July 2014.

The College selected the IPI model as the procurement route under its application for funding under the Government’s Institute of Technologies programme and the Black Country LEP. The first Case Study described how the designers, specialist contractors, constructors and project coordinator/integrator were appointed at the outset under an “Alliance Contract” which has been developed for fully integrated collaborative working under the IPI model; it concluded with a description of the early Phase 1 activities.

The second Case Study started with particular focus on benchmarking: it became clear that there was no ready benchmark that reflected the functions in the brief for this facility; and described how the appropriate benchmark has been objectively derived. It then described how the alliance members through their integrated project team (“IPT”) developed a project solution which (a) had the support of the independent facilitator and risk assurers and (b) was approved by both the Insurers and the College as being “fit for the purpose” set out in the strategic brief at an agreed target cost that has an adequate allowance for technical and financial risks. It highlighted the further progress in Phase 1 in terms of innovation in various forms, the importance of BIM, and the learnings about how even better results can be achieved next time; it described the process up to the end of Phase 1 and the inception of the new “Integrated Project Insurance” policy, which led to the “Decision to Build” in the 3rd quarter 2020; and lastly reported on initial progress through Phase 2 as detailed design and implementation proceeded despite Covid.

This Case Study, the last in the series for this pilot project, concentrates on the outcomes, both in terms of the finished product and also the time and cost of delivery and the operational status. The importance of informed and realistic benchmarking, already discussed in Case Study 2, is revisited. Feedback from both the client and members of and suppliers to the alliance is included, not least because it includes key lessons for future improvement on the Insurance Backed Alliancing journey.

Project summary

Project timeline

- 8 March 2018: invitation for Expressions of Interest (“EOI”) in OJEU

- 15 March 2018: Industry Day

- 16 April 2018: return of Standard Selection Questionnaire (“SSQ”)

- 4 June 2018: return of Invitations to Tender (“ITT”)

- 18 – 29 June 2018: interviews and behavioural workshops

- 4 July 2018: announcement of Award under OJEU

- 2 August 2018: Alliance Contract signed by all the Alliance

- 27 September 2018: Commercial Alignment of Alliance Partners completed

- 27 September 2018: Phase 1 start and design validation

- 25 January – 18 April 2019: suspension awaiting approval of initial funding from

- 15 May 2019: admission as a trial project under the Cabinet Office/Constructing Excellence Trial Projects Delivery Programme

- 24 February 2020: commencement of site enabling works

- 24 March – 18 May 2020: suspension due to Covid-19

- 8 June 2020: release of balance of approved funding of £17.36m by DfE, enabling the Hub to

- 12 August 2020: Phase 1 solution development complete

- 12 August 2020: Phase 2 commencement following IPI policy

- 31 March 2021: confirmation of impacts of Covid-19 Review Event

- 23 August 2021: target completion (after 9-week extension)

- 21 October 2021: official

Key project features

- Integrated collaborative working assured

- Strategic brief that includes affordable investment target

- An IPI “Alliance Contract” that empowers the team

- Alliance owns solutions and outcomes

- Financial exposure capped to insured limit, client financially responsible in the unlikely event it exceeds this limit

- Outcomes insured – including overspend

- Fitness for purpose as defined in the Strategic Brief

- Efficiency gains whilst cutting process waste

- Free of liability inhibitions to BIM

- Free of insurance limitations for SMEs

Client objectives and vision

Vision

The IoT will support the development of a technically skilled workforce responding to the region’s STEM skills gap and the deficit of adults with L4+ qualifications. The IoT’s focus will be careers not qualifications including pathways for product design engineers; manufacturing technology engineers; digital engineering technicians (Building Information Modelling); construction assembly technicians; science industry maintenance technicians; biomedical systems engineers.

Strategic Brief

Accommodating over 1,200 learners per annum by year 5 of operation, including full- time, part-time and Apprenticeship study, the outline planning and funding applications for the IoTT main campus were for two distinct buildings comprising the following facilities:

- Construction Manufacturing workshop for 36 learners

- Advanced manufacturing labs and workshops for 90 learners

- Materials testing laboratories for 40 learners

- BIM suites for 120 learners

- Medical engineering suite for 36 learners

- Laboratories for 160 learners

- A lecture theatre for 100 learners

- A conferencing facility for 35 delegates

- Learner services facility

- Suites of rooms including IT, general classrooms, tutorial/meeting rooms

- A Café bistro for 140

- Common room spaces for each building

- ‘iPoint’ learning zones for 80 learners

- Staff rooming for 60 staff

- Sufficient associated storage facilities

Success Criteria

- Predictability of completion at a cost which is below the agreed Target Cost.

- Build quality to give an exemplar to learners and staff, with a high-quality learning environment that inspires.

- ‘Function over form’ to ensure the best possible facility for training within the investment target and the maximum possible delivery space is achieved within the envelope.

- Highly efficient methods, including off-site manufacturing and new methods of construction are considered in the design and delivery of IoTT eliminating waste in materials, processes and procedures.

- It should create 20 apprentice positions and a live training environment for the college and its partners as part of its construction.

- Leading BIM level 2 or better methods and technologies are adopted from commencement including soft landings considerations from BSRIA from the start.

- Durability of the building making it robust, easy to maintain and clean, with life-cycle cost considered in all capital investment decisions.

- Design, delivery and operation of the IoTT will engage all organisations in leading edge practices. All parties will promote their involvement and the successes achieved and provide legacy support to the educational functions to be delivered.

- It is preferred that the buildings will be predominantly naturally ventilated.

- Flexibility of the facility to be remodelled to meet future changes in demands and training methods, rather than adaptability for short term change.

- Design aesthetics of the building must make a statement of its quality and that of the Institution it represents.

- Where possible local and regionally based staff, operatives and SME organisations will be involved in delivering the project.

- The construction site will be well organised and clean, highlighting the aspiration of the efficient procurement and construction methodology being used.

- Whilst the IoTT is not required to achieve BREEAM excellent, there is an aspiration that the best from BREEAM combined with a highly efficient external envelope, in terms of air tightness and thermal efficiency, will result in a building of very low running cost.

- The IoTT is required to achieve an EPC A rating.

Monitoring and control of costs

As explained in Case Study 2, Phase 2 (initiated after the inception of the IPI policy) was split into two stages to allow the alliance to establish to what extent the effects of Covid could be mitigated. Civil works on site had originally been suspended for 8 weeks, but due to digital twin, design development and detailing by the IPT had continued apace, and the effect of the funding delay on the go-ahead for the Prototype Hub was absorbed. After taking stock of the overall situation the alliance confirmed, on 31 March 2021, the basis for proceeding with Phase 2B:

- Target Completion would be extended by 7 weeks to 9 August 2021

- The Target Outturn Cost would be increased, on account of the above, to £17.579m.

This staged process incidentally allowed for adjustments in staffing between the partners due to the scope or programme refinements to be recognised, albeit without any change being made to the total “ringfenced sum” for the alliance’s corporate overheads and profit. Such flexibility after initiation of Phase 2, for a limited period while detailed design is still being completed and construction resourcing is being established, is clearly beneficial and steps have been taken to incorporate appropriate provisions into ongoing alliance contracts.

The alliance managed the programme to completion without further slippage from Covid, but Review Events for late/insufficient power connection by Western Power and information flow for FF&E from the College resulted in a further extension of 2 weeks to 23 August 2021 and a revised Target Cost of £17.686m.

Other issues which were accommodated by the alliance during 2021 without adjustment to the Completion date or Target Cost included:

- Flooding to external work areas, causing alternative sequencing of work

- Redesigns due to materials shortages arising from Covid

- Adjustments to pond construction and finish to achieve acceptable aesthetic and maintenance regime

- Accommodating changes in the use of some laboratory spaces, requiring service route alterations, with associated builders work.

Outcomes

Client Statement

“The College’s bid for the Institute of Technology programme was based on the Integrated Project Insurance (“IPI”) model of procurement and delivery in order to ensure the best value for money and predictability of outcome that was secured on Advance II, the College’s first IPI project.

The outcomes on our IoT facility for advanced manufacturing, modern construction methodologies and medical engineering have been truly exceptional: the alliance’s collaborative culture alongside use of a truly federated BIM model minimised set-backs from both Covid-19, as well as the more usual design issues experienced on a traditional project, especially on site. Final design and build cost was about £58/m2 below the DfE’s standard schools benchmark and about £130/ m2 below the bespoke benchmark derived for this complex facility; and running costs are already projected to be 62% below the Advance I building that was procured on traditional “design & build” to BREEAM Excellent standards.

IPI has transformed the College’s experience with the construction industry, and we commend it to DfE and other departments that spend public money.”

Steve Johnson, Executive Director of Estates and Capital Projects

Outcomes – time

As already explained, the use of digital twin enabled the IPT to proceed with the design development and detailing independently of the site; and after the 8 weeks initial suspension the early site works proceeded with appropriate distancing precautions.

Key statistics were:

Original completion date; 21 June 2021

Review Event for Covid delays: 7 weeks

Review Events for power & FF&E: 2 weeks

Extended Completion date: 23 August 2021

“Critical need” date:22 September 2021

Actual Completion date: 23 August 2021

Official Opening: 21 October 2021

Outcomes – cost

As explained, costs were actively monitored and controlled throughout, with the dedicated involvement of an alliance cost manager who reported to the alliance manager and members. Opportunities and risks were identified from the outset and managed down progressively in order to capture the benefits of innovation as well as minimize the adverse effects of risks.

There was an early crisis as it was found, not surprisingly, that the DfE’s benchmark of £3,551/m2 for a school was incompatible with a further education facility of 4,750 m2 for the transformational sectors of advanced manufacturing, modern construction methodologies and medical engineering. Based on the alliance’s initial design solutions the gap was £1.8m. The incentive scheme which distributes overspend as well as savings to all alliance partners, however facilitated a transformation of the outcome: adjustment to ground remediation measures, revisions to acoustic and thermal treatment, adjustments to site compounds resulting in reduced project overheads and a comprehensive transition to collaborative challenge utilising the skills of all alliance partners and suppliers. Eventually DfE recognised some underfunding and “exceptional items” identified by the College and made available further funding, enabling the Target Cost to be raised to £17.359m.

In parallel, as explained in detail in Case Study 2, a functional analysis of the client’s requirements for the facility was populated by RLB, the FIRA, using BCIS cost data; and in order to preserve independence from the Alliance’s developing cost plan, the standard percentages for professional fees and contingencies used by DfE were also applied, together with VAT. The resulting “IoT bespoke” benchmark was £3,726.97/m2, or £17.703m.

Key statistics were:

| DfE final | IoT bespoke | |

| Benchmark | £17.359m | £17.703m |

| Review Events | £0.327m | £0.327m |

| Target Cost | £17.686m | £18.030m |

| Actual | £17.417m | £17.417m |

| Saving £m | £0.269m | £0.613m |

| Saving £/m2 | £57/ m² | £129/ m² |

The saving of £269k therefore became “gain-share”, divided between the alliance members as agreed in the alliance contract. The client’s share was £59k.

Alliance partners’ feedback

Shortly after completion “open and honest” feedback was sought from the alliance partners and suppliers. Thirty-three responded.

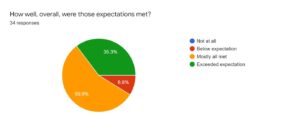

The pie chart below indicates the extent to which project experience met expectations.

The excerpts below show the high standards of collaboration expected but also the ways in which the partners thought that collaboration could in future become more productive and cost-effective.

Excerpts:

This being project number 3 for me, I knew that as long as the right people were in the team the process would allow us to work together to tackle risks and problems but also realise opportunities when they were apparent. This though was by far the best and most efficient team I had been part of so far with IPI.

The transparency and openness enabled greater appreciation of what people were doing which meant you could engage with people differently. You potentially considered do i need to ask this and is this appropriate. Traditional approach you would would ask/request everything to ensure you are covered.

More time could be invested in aligning the team, looking at team dynamic and behavioural profiling (Alliance Board and IPT). Understanding each other better and learning how to adapt approach to connect better.

There were occasions where collaboration came into its own (when over budget). Project Insurance relaxed the territorial attitudes that come with traditional contracts & allowed us to blend responsibilities.

It takes a bit of convincing that such a collaborative approach is possible – especially when used to the cut-and-thrust of traditional contracting – but once experienced all parties can promote the benefits to those who have not experienced IPI’s.

There was a great focus on the costs; even if certain individuals didn’t see the cost plan as everyone’s responsibility, the majority certainly did and by holding regular meetings to keep the team up to speed (usually including board members), I think the project team and board members had a greater understanding and appreciation of the cost plan – which ultimately paid them back with a gain at the end.

We need to spend more time in Phase 1 to engage Suppliers with the IPI process.

Those who engaged generally did it well, but not all did. Unsure as to whether this was our failing or theirs.

I don’t think we were confident enough to open ourselves properly to specialists taking on the design elements despite them being better suited to doing so. Thinking Steelwork in particular here.

Had the alliance been as focussed on gaining opportunities consistently as they were at mitigating risk we’d have done better! Also programme was not given the same scrutiny as cost – we need a simpler way of reviewing – e.g.’ reason we caught up on some M&E is because the containment took 2-3 days not the 5 on the programme – we need to be as lean with programme as we are with cost.

Whenever the Target Cost was showing as under threat or under pressure, the team reacted quickly to change that. I think the reporting of costs and cash was managed well which aided this, proving that a construction QS and a separate individual for the ACM role is certainly the way forward. I don’t think the companies have to be independent for this to work, but the roles and therefore the people should be.

Guidance on the IPI Model

The Prospectus on Insurance Backed Alliancing is accessible at https://constructingexcellence.org.uk/wp- content/uploads/2018/04/201803-Prospectus- rev-1-Mar-2018-002.pdf

Authors

This case study has been developed for Constructing Excellence by Martin Davis, as IPI Mentor, with invaluable assistance from his IPInitiatives’ colleagues Louise Lado-Byrnes (Joint Alliance Manager), Phil Sims (Alliance Cost Manager) and the members of the Alliance.

Background: Trial Projects programme

The Government Construction Strategy aims to change the relationship between clients and the entire supply chain within the industry. The trial projects perform a central role in delivering the Strategy’s sustainable 15-20% reduction in costs and have been testing three new procurement models (Cost-Led Procurement; Integrated Project Insurance; Two Stage Open Book) that were proposed by industry and developed by a joint task group. Case study reports are therefore an output of monitoring the progress and outcomes of the trial projects. They are produced at four stages: Kick-off Meeting; Brief/Team Engagement; Decision to Build; Build and Occupy. Other case study reports can be found at: http://constructingexcellence.org.uk/cabinet- office-trial-projects/

Project contacts

For further information on Insurance Backed Alliancing under the IPI model or to introduce a potential trial project, please contact Martin Davis, IPI Mentor for the Cabinet Office, at [email protected] or Kevin Thomas at [email protected] or Louise Lado-Byrnes at louise.lado- [email protected]

Successful applicants who are accepted onto the Cabinet Office’s Trial Projects Delivery Programme will then have access to the latest versions of the Procurement documentation and system, Alliance Contract, Supplier Alliance Subcontract and IPI Policy.

March 2022

Comments are closed.