The third panel from the Constructing Excellence Conference 2024, ‘Delivering Tomorrow Today’, focused on Future Major Projects. The panellists explored key themes such as productivity, standardisation, managing costs and programmes of major projects and scaling down from major projects to smaller projects.

We were pleased to be joined by industry professionals with experience in Major Projects, who shared their views on how to deliver a future for construction. The session was Chaired by John Oliver and the panellists included James Franklin, Hannah Kitcherside, Karine Bartle and Emma Whigham.

Standardisation

The construction industry seems to be reluctant to embrace standardisation though it comes up time and again as a key strategy to reduce costs, time and waste, consequently improving productivity and efficiency. Often, we think that what we do is special or unique and therefore standardisation won’t work. However, standardisation does not need to prevent individuality- a standardised approach can still be tweaked to meet regulations, specific needs, etc. but having a base design saves time and stops us from having to start from scratch on each project.

Whilst it is possible to adjust a standardised approach where necessary, it is important to ensure there is consensus around what standard looks like to ensure we don’t move so far away from the base design that it is no longer recognisable. This requires upfront consultation at the beginning of a project to ensure all stakeholders agree to the standard design.

To unlock the value of standardisation the design or procurement route may need careful consideration, particularly within some commercial models, particularly when linked to incentivisation. We need to work closely with clients from the outset to ensure standardisation can be factored into contracts and agreements, enabling all stakeholders to understand and access the benefits of the approach.

Scaling Down

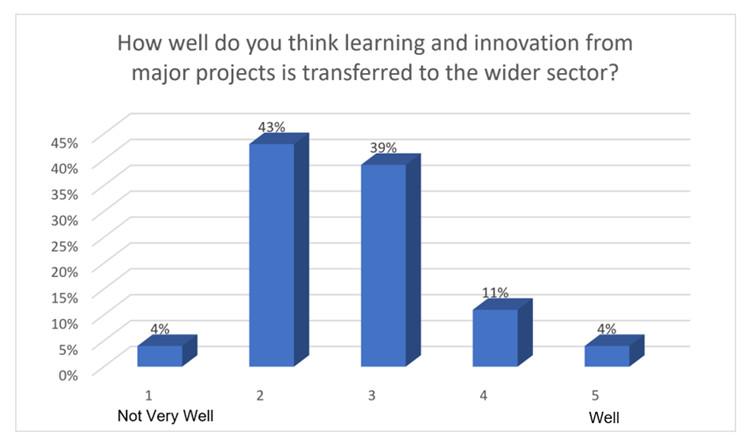

Major Projects are a huge catalyst for change within the industry. The big question is how do we pass learning down the supply chain? Not just the supply chain on a single project, but to other key organisations and their supply chains to share knowledge, innovation and productivity gains widely across the sector. Our delegates recognised this challenge through the polls they completed during the conference…

Client engagement is key to spreading lessons learned down the supply chain and transferring new approaches across projects. Working closely with clients enables them to gain a greater understanding of the innovative techniques and technologies being applied on major projects, enabling them to take this forward and require the same from future endeavours, increasing the expectation of innovative approaches across the industry. If clients demands and expectations are high, construction will need to respond to this.

As an industry we also need to improve our knowledge sharing strategies. It’s important that examples of innovation are visible across construction to bring greater awareness of the techniques, tools and approaches taking place. This will enable major projects to better disseminate their lessons learned among smaller organisations and projects to transfer new knowledge further down the supply chain.

Managing Cost and Programme of Major Projects

Managing the cost and programme of major projects can be challenging but there are real example of how this is being done, for example HMP Five Wells, which was delivered on time and on budget, demonstrating the true benefits of alliancing, collaboration and standardisation. The challenge is in ensuring that the learning gained from major projects such as this is retained and shared to benefit the wider industry.

Leadership is crucial in managing costs and programmes of work as strong leaders are needed to ensure projects are not impacted by changing objectives and ambiguity. These leaders need to ensure appropriate contracting arrangements are utilised to ensure clarity and clear outcomes within a programme of work to prevent disruption during the ongoing delivery. Too much change can impact cost, for example, when materials are ordered and abandoned due to change of plans. The same applies to the design process- ambiguity leads for too much room for change and adaptation over time. Plans need to be clear and finalised before beginning a project to prevent changes which can cause cost, time and material waste.

Leadership is crucial in managing costs and programmes of work as strong leaders are needed to ensure projects are not impacted by changing objectives and ambiguity. These leaders need to ensure appropriate contracting arrangements are utilised to ensure clarity and clear outcomes within a programme of work to prevent disruption during the ongoing delivery. Too much change can impact cost, for example, when materials are ordered and abandoned due to change of plans. The same applies to the design process- ambiguity leads for too much room for change and adaptation over time. Plans need to be clear and finalised before beginning a project to prevent changes which can cause cost, time and material waste.

Politics do have a part to play in the leadership of major projects. Clear decision making is needed regarding which projects should come first. There are number of initiatives doing wonderful work but their priorities and intentions do no align, therefore, we need to be able to identify those that should be prioritised and understand the ‘why’.

Standardised design will be an effective strategy in managing the cost and programmes of major projects as a single reference design, as being undertaken by NHP, will ensure clarity as there will be only one way to deliver a specified product e.g. hospital. Locking this down in commercial terms will ensure that, no matter who the client is, the design doesn’t change, reducing potential for waste materials, improving predictability of time scales and cost and ensuring all stakeholders understand and can deliver on major project requirements.

Productivity

Productivity is a major challenge and plays a big part in delivering projects, on time, on budget and to specification. So, what’s stopping us from increasing productivity and improving the efficiency of the industry?

Good logistics are a crucial, and often underrated, part of a construction project. So much time and money can be wasted waiting for materials to be delivered which is completely avoidable if greater consideration is given to logistics at an early stage. We need to ensure early engagement with the whole supply chain, including the logistics team, as well as ensure our subcontracts and commercial agreements allow for effective logistics management, as often logistics can get buried within these arrangements. If we begin to decouple the supply chain, we can investigate what we could do differently and what expertise we can draw from to make improvements and deliver value.

“Good logistics is about getting the right materials to the right place at the right time. If we can ensure this is happening, we will improve productivity”.

Karine Bartle

Another barrier to improving productivity within construction is benchmarking. We need to establish effective methods of measuring productivity that go above and beyond cost alone to establish a baseline measure and determine where a project is at its conclusion. Other potential factors include redesign, output, waste generation, delivery efficiency, quality, and workforce attrition.

More agile decision making is essential to efficiency when delivering projects as time wasted on this can cause delays, material and money waste. Being able to make quick decisions, and having the processes and strategies in place to support this, can prevent lost time and enable projects to run smoothly despite challenges. All major projects are different so we must get better at applying new learning to projects in different ways.

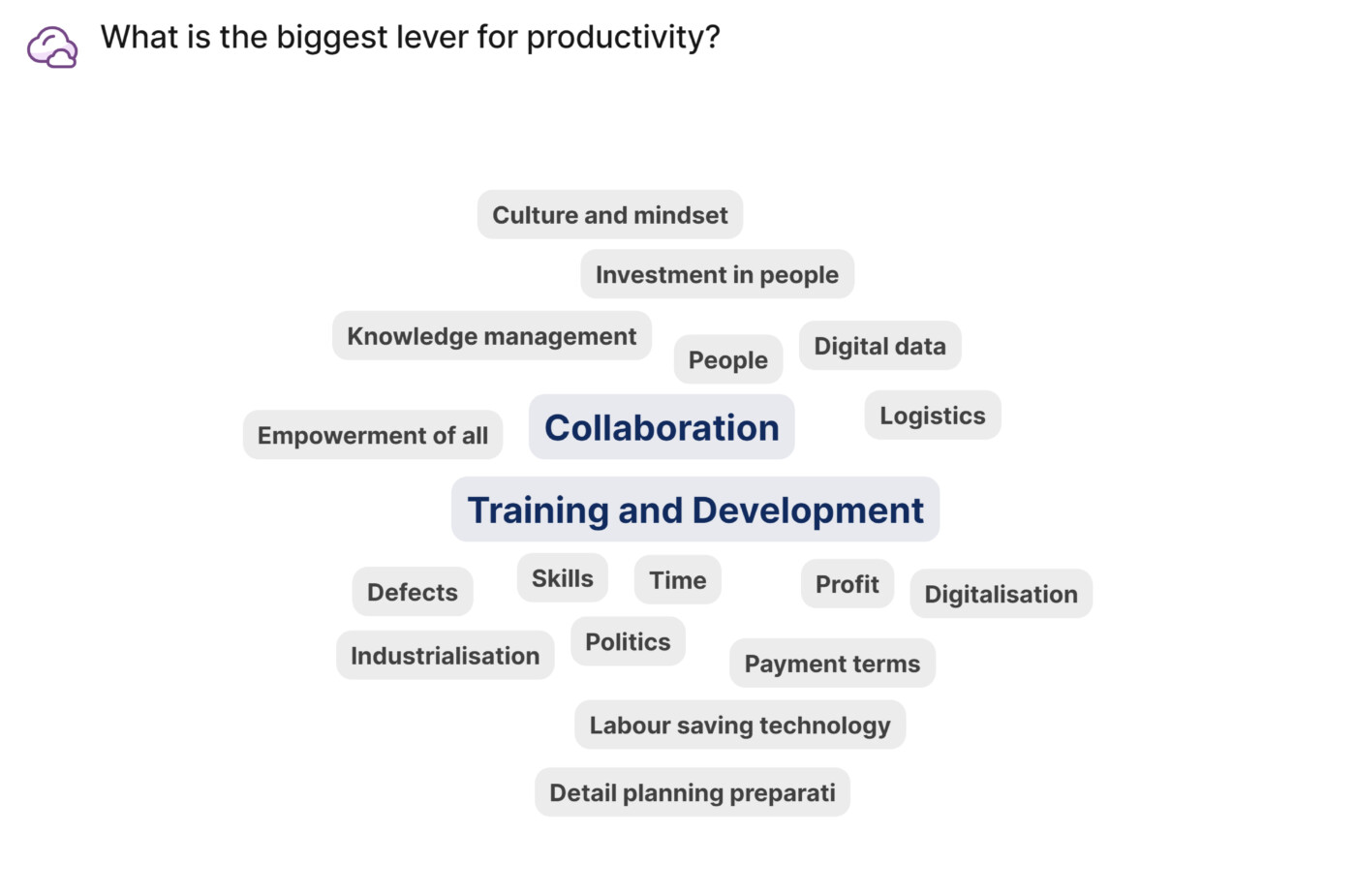

Conference attendees were asked for their opinions on the biggest levers for productivity:

Together We Can Deliver a Better Future

Productivity, management of costs and programmes, standardisation and sharing lessons learned from major projects down the supply chain are all interlinked in improving efficiency within the industry.

“As an industry we know what we like and like what we know.”

John Oliver

We need to move away from applying the same old tools and techniques and ensure we are embracing new strategies that will drive improvement within construction and enable us to keep up with the changing times, delivering a better future climate and society.

Thanks to Our Sponsors