Many researchers into construction comment on the inherent conservatism and lack of innovation in the industry. Practices and methods are slow to change and develop; what has changed in a generation? The Latham and Egan reports of 20 years ago identified hurdles to efficient working that still remain firmly in the path of progress today. Contrast this to manufacturing where the race is on to lead the so-called fourth industrial revolution. The first was harnessing coal and steam; the second, the introduction of the production line; the third the use of automation. The fourth will see factories transformed by digital technology.

Why has innovation not transformed the construction industry in the same way that it has manufacturing? Isn’t it because in construction innovation is not rewarded? Perhaps even worse than that, the traditional tendering and procurement methods actively discourage innovation. The supply chain offers only to build what the client proposes, it is not incentivised to offer alternatives. To offer an alternative bid is a costly venture with a limited chance of success and there is no guarantee that the bidder’s novel approach will not be plundered by the client without acknowledgement. Thus with only the client engaged in original thinking, the innovative potential of the vast bulk of the industry is completely untapped.

If however a procurement method was employed that rewarded innovative thinking then the intellectual potential of the supply chain could be mobilised to drive the industry forward. This is precisely what LU’s Innovative Contractor Engagement (ICE) process does.

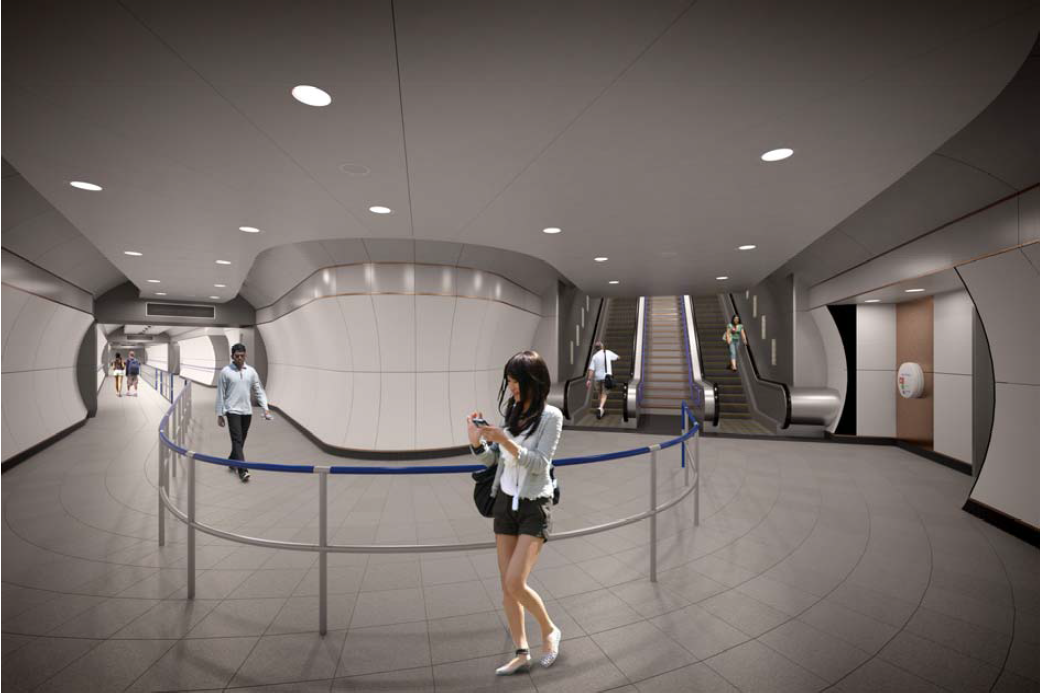

ICE was used to procure the £ ½ bn design and build contract for Bank Station capacity upgrade scheme. https://www.apm.org.uk/news/how-innovative-contractor-engagement-ice-achieved-45-improvement-benefit-cost-ratio-what-can-yo

This is not hot news, the contract was awarded in 2013 but nevertheless the success of the method is worth reflecting on:-

- 45% increase in the benefit to cost ratio

- 19% increase in Journey Time Social Benefit over the 60 year project life

- 10% (£61m)reduction in EFC

- 5 week reduction in station closure time for construction (saving £35m in social dis-benefit)

Since then LU employed the same process to award the £40m Bakerloo Line Link in 2014, a passenger tunnel that is a component of the Crossrail project, enhancing value by 40% and demonstrating that the methodology holds good for smaller schemes also.

It is initiatives like these that must be employed widely if the Construction 2025 target of a 30% reduction in costs is achieved.

We at the CE Procurement Group believe that the Construction 2025 target of a 30% reduction in construction costs cannot be achieved without wholesale abandonment of the traditional procurement models. In acknowledgement of this, Innovation was the subject of the Constructing Excellence members forum on June 10th; you can find Don Ward’s report on the day by following this link https://constructingexcellence.org.uk/how-does-construction-embrace-innovation-members-forum-10062015/

Charles Mills, Head of London Underground Crossrail and chair of the Constructing Excellence procurement group

This blog is the first in a series prepared by members of the Constructing Excellence Procurement Theme Group to provoke debate and seek to provide thought leadership on a crucial aspect which we see as a major barrier to improving the productivity of the sector. Comments are welcomed on the Constructing Excellence LinkedIn page or on Twitter using the hashtag #CEprocurement.

Sign up below to get the next instalment of this series emailed to you directly:

[wysija_form id=”2″]