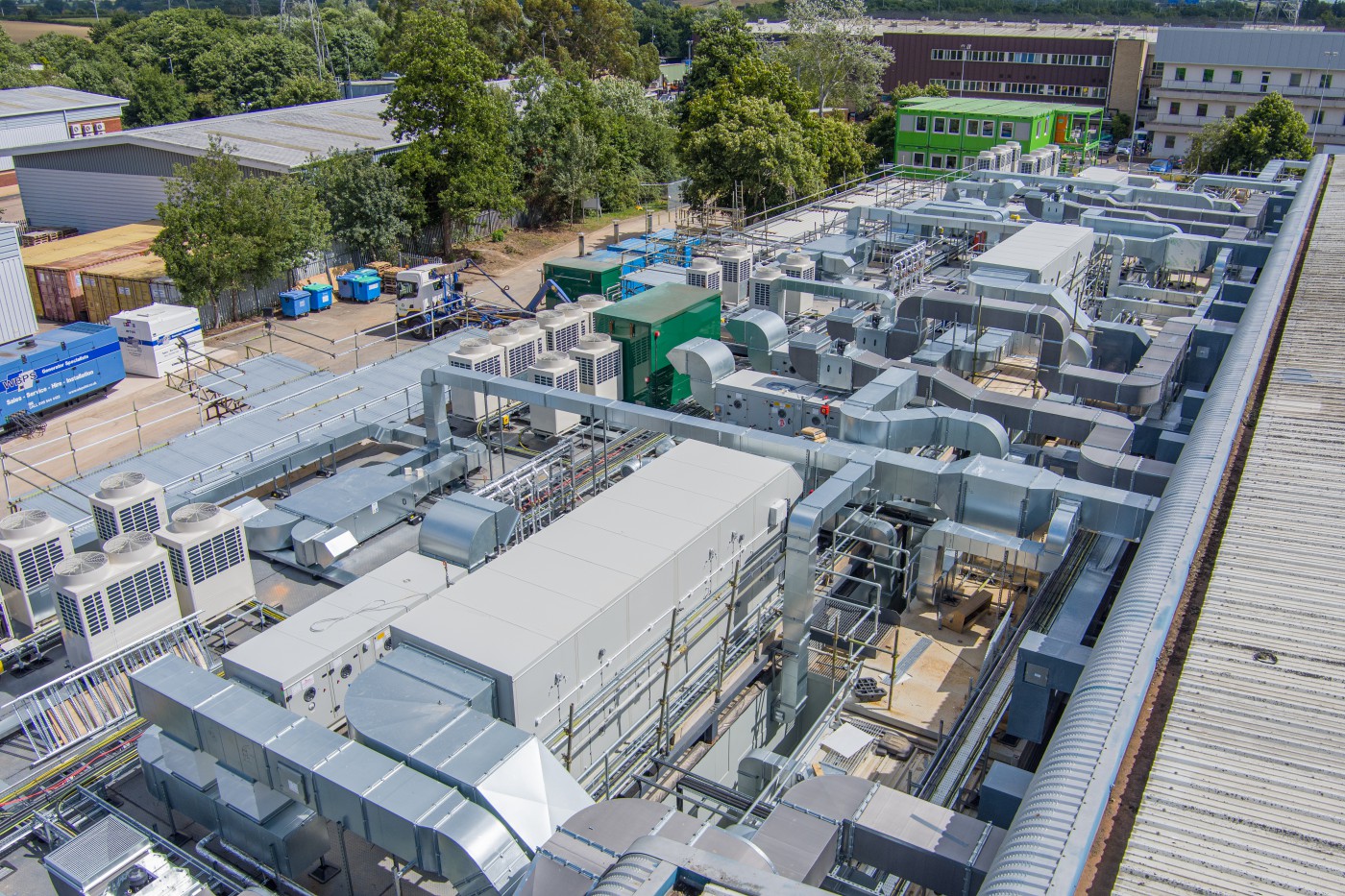

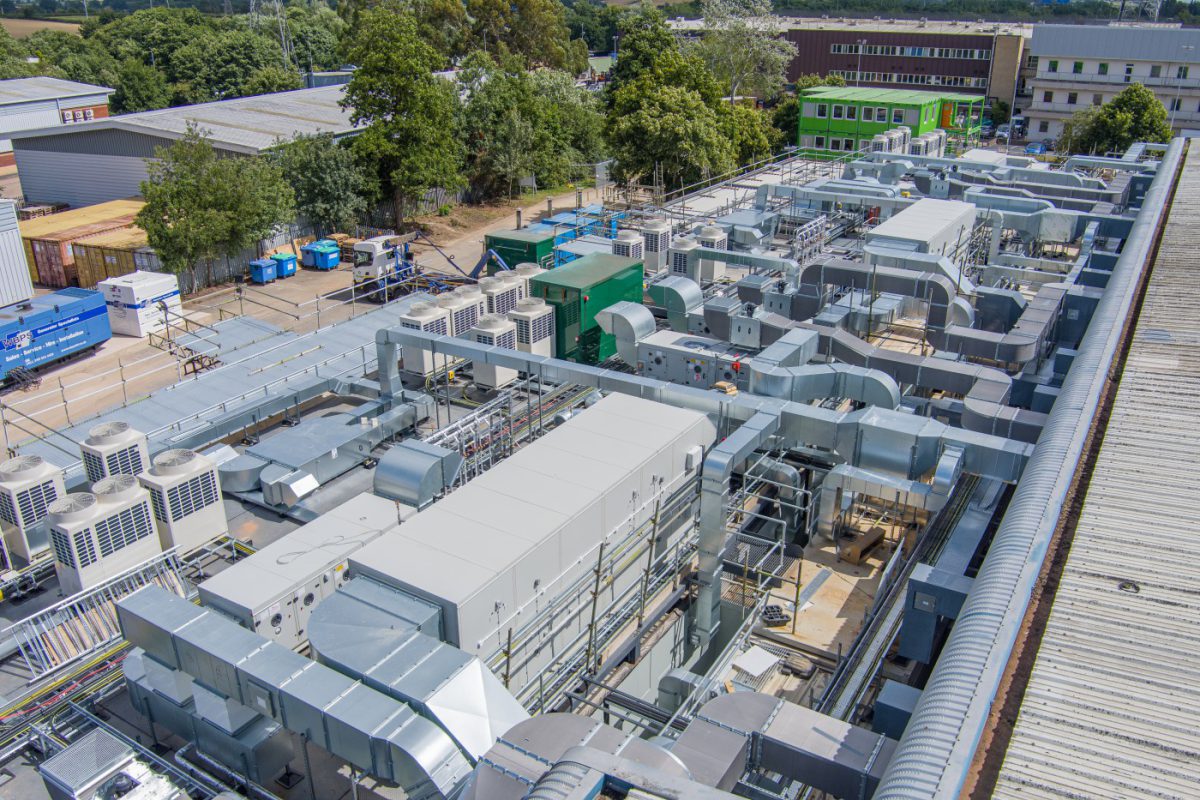

Under the most testing circumstances, BAM and the entire, amazing project team worked tirelessly to deliver a superb, fully functioning, 116 bed hospital facility for the people across the South West. Delivered in just 57 days, all during the peak of the first COVID-19 lockdown, this was a major engineering and logistical challenge, turning a redundant Homebase store into a permanent, mini general hospital.

Due to the critical nature of the facility, programme was key, and, through collaborative working and innovative thinking, the facility was completed in just 57 days, including eight days demolition and site preparation and 49 of construction. Whilst called a Nightingale, this facility was a full-scale construction project, re-purposing a former Homebase DIY retail unit with no suitable infrastructure into a full acute facility with the requisite compliant ancillary space and welfare areas.

This scheme delivered more than a temporary facility, as other Nightingale projects were designed to do. Nightingale Hospital Exeter provides a permanent, mini-General Hospital, close to the strategically important M5-A38-A30 communications network and benefitting the whole region. Over 80% of the total £23m project spend went to supply chain partners within a 45-mile radius of the site, including many SMEs. BAM initiated a strategy to keep operatives on site as much as possible, employing three local mobile catering companies to provide free food and beverages, including over 100,000 individual bottles of water.

To reflect the need for flexibility and operational resilience, another factor that differentiates Exeter from similar schemes is compartmentalisation. We created five areas of between 22 and 24 beds, which can be used for different purposes – allowing the Trust to decide what it wants to do with this new facility, providing the flexibility subsequently to change functionality to meet demand.

The timeframe, programme and logistics all presented huge challenges, amplified by project conception and delivery all taking place during a full national lockdown in response to the global Covid-19 pandemic.

Over 2,500 people were involved on this project, with 467 on-site at the busiest time, all during the first national lockdown at the height of the COVID-19 pandemic. This presented a huge logistical challenge which was managed by strict social distancing segregation, hi-tec bio security and on-site medical teams, all resulting in zero reportable incidents and no COVID-19 issues.

The design team was just 24 hours ahead of construction, sometimes less, and there were elements of work designed one or two days, or even hours, before they were installed. The design went through many iterations on a daily basis and the team worked tirelessly to assimilate the changes, making sure they just kept in front of the installation team. Ultimately the success of this project was founded on the true partnership between all parties and o BAM’s long-standing relationship with architect, Stride Treglown, engineers Arup and site-based MEP design team, SDS.